The Use of NDT for Surface Defects

Nondestructive testing (NDT) for surface defects requires solutions that can effectively probe complex surfaces that are rough or include tight corners. Therefore, technicians need a surface-oriented approach—such as eddy current array (ECA)—that can easily overcome the challenges of unconventional contours.

However, ECA technology alone is not enough to get the job done. Technicians also need quality instruments and probes that can enhance array capabilities. With efficient equipment, analysts can achieve a more customized inspection regimen on both smooth and rough surfaces.

The Benefits of ECA for Surface Defects

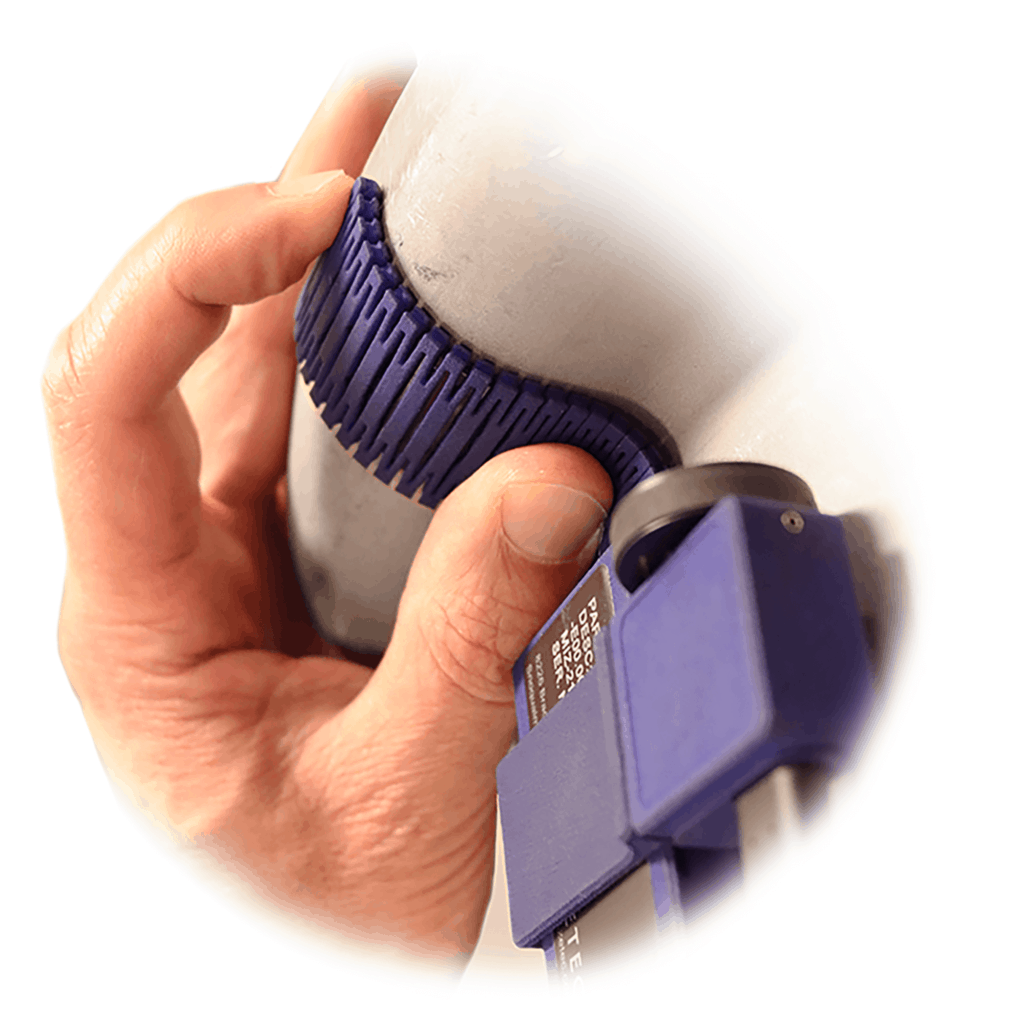

Unlike standard pencil probes, ECA probes can conform to various curvatures and geometries. As a result, users can apply a single probe to quickly inspect surfaces. With more advanced, flexible ECA probes, technicians can achieve faster inspections by changing out probe coil sets in under a minute to handle different surface materials.

| Note: To maximize ECA results, find ECA instruments with top-notch signal quality. When an ECA device is paired with a highly flexible array probe, technicians can reduce inspection times exponentially. |

With a single pass of a quality ECA probe attached to a highly capable ECA instrument, the inspection can read transition zones and heat-affected areas on non-ferromagnetic materials.

Highly flexible ECA probes offer additional versatility including:

- Durable wear surface options that safeguard the array coils on rougher surfaces or on polished and smooth surfaces

- A detachable encoder that can pinpoint flaw locations and dimensions for greater accuracy

Best of all, technicians can achieve quality data at a lower cost and shorten inspection times in the process.

The Inspection of Diverse Surfaces

With ECA, the coils must be in direct contact with the tested area to achieve sound signal quality. Matters can grow more complicated in the event of differing surface compositions that can obscure signal quality. The wrong ECA probe can adapt to complex surfaces and welds haphazardly, producing skewed data.

That’s why analysts can benefit significantly with flexible ECA probes that feature interchangeable coil sets which can bend and adapt to different situations. A versatile probe gives users the ability to maintain alignment while sliding the probe across the surface.

Take note of some different applications

- Smooth and Complex Surfaces: A tape-based ECA probe can inspect smooth and unconventional surfaces. This type of probe can also find small flaws that usually escape detection with other NDT alternatives.

- Thick Plates: Choose a low-frequency probe for thicker materials. These probes can also tailor to various surfaces.

- Weld Toes: When dealing with weld toes, the array function isn’t enough. However, the addition of +point coils allows analysts to inspect weld toes without further hassle. Plus, technicians will benefit from specialized handles fitted for complicated welds like butt welds.

Butt welds are one of the most problematic designs because they’re prone to cracking or corrosion. However, analysts can test butt welds through NDT choices like phased array testing (PAUT) or ECA. PAUT is best suited for volumetric inspections, while ECA is preferable for achieving surface data.

NDT for Surface Defects with ECA

Eddy current array technology is the ideal choice for surface-based inspections. An advanced ECA instrument features a handheld ergonomic design with long battery life and an intuitive color touchscreen interface. The flexible eddy current array probe provides various coil set options that can eliminate the need for purchasing additional probes. Other NDT options (i.e. magnetic particle testing) don’t provide the same level of versatility or detailed readings as ECA. ECA users can benefit from advanced technologies that can read small and large flaws alike.

Any technician using NDT for surface defects should include ECA in their arsenal due to the ability to test varying surfaces using a handheld instrument with a single probe. Without quality equipment, asset owners must utilize multiple methods and/or devices to achieve the necessary data. With ECA, however, users have more time to find additional flaws that could degrade asset integrity over time.

Zetec is a major provider of quality ECA probing measures. Contact us today to get a custom inspection plan and further guidance on how best to apply ECA techniques.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.