NDT Solutions for Weld Inspection and Test Procedures

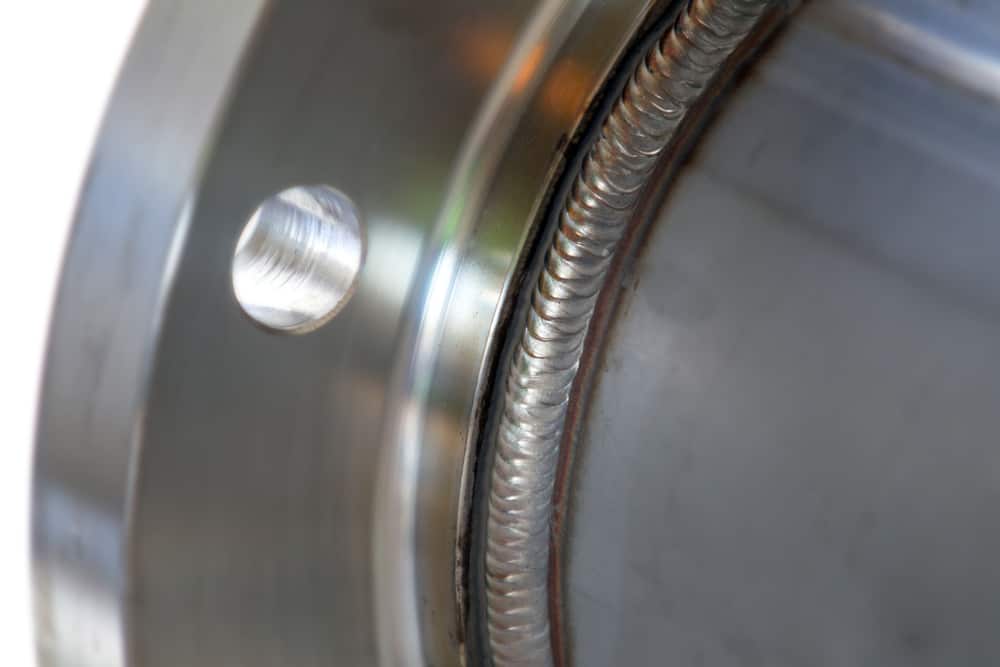

Weld inspection is an integral part of industrial quality control. The welding process can lead to the presence of flaws due to the metallurgical changes a material undergoes when exposed to heat treatment or inaccurate weld parameters. To ensure welding operations go as planned, and to test the quality of the fabricated component, advanced non-destructive testing (NDT) technology for weld inspection is preferred by many industries.

The inspection of the weld integrity includes identifying flaws, such as lack of fusion, surface cracks, corrosion, inclusions, and porosity—which can be difficult to detect during visual inspection alone. With eddy current and ultrasonic inspection technologies, manufacturers have been able to perform weld inspection and testing procedures without having to compromise the structural integrity of components.

NDT Solution for Simple and Complex Weld Inspection

The implementation of non-destructive testing can be complex requiring specialized and advanced probes, instruments, and techniques. The challenge can be even more intense when inspecting components with complex geometries. Zetec’s weld inspection scanning solutions including the WELD Crawler and ElbowFlex Scanner provide an ideal solution in identifying flaws during weld inspection and test procedures of simple and complex geometries.

Zetec’s WELD Crawler provides various advantages for facilitating ultrasonic weld scanning with features such as:

- Easy transformation from axial to circumferential weld scanner

- Low clearance for use in confined spaces

- Optimal positioning for complete coverage

- Compatibility to work with a wide range of diameters and wall thickness up to six inches

The ElbowFlex Scanner provides an easy ultrasonic inspection solution along curvatures such as pipe elbows. Its benefits include:

- Ideal for detection of corrosion, wall thickness, and mid-wall lamination

- Ability to adapt to straight as well as curved paths

- High-resolution C-Scan imaging for accurate analysis

- Fast inspection with magnetic wheels for fast and easy operation

To sum it up, Zetec’s scanning for advanced and reliable weld inspection provide the advantage of:

- Flexibility

- Adaptability

- Precision

- Complete coverage

Weld Inspection and Test Procedures Resources and Applications

The quality of testing procedures for welded components is highly dependent on the ability of non-destructive technologies to identify discontinuities from different types of welds. This is essential for industries to meet their quality, safety, and productivity goals. We have compiled a list of resources that explain how NDT solutions can help industries in their weld inspection and test procedures.

- Improve Nozzle Weld Inspections (Webinar)

- Improve Austenitic Weld Inspections (Webinar)

- Austenitic Weld Inspections (White Paper)

- Improve Inspections of Thick Carbon Steel Vessel Welds (Webinar)

- Stainless Steel Weld Inspection (Application Note)

- Long Seam Weld Inspection (Application Note)

- Boiler Tube Weld Inspection (Application Note)

- Phased Array UT and TOFD Deliver More Accurate Pipeline Weld Inspections

- NDE 1-2-3: Inspection Techniques for Weld Applications

- Around the Bend (Pipe Elbow Inspections)

Product Recommendations for Weld Inspection and Test Procedures

To help you meet your industrial specification, Zetec offers a wide range of NDT solutions. We have compiled a list of our advanced industrial inspection and analysis solutions to assist you in the selection of suitable NDT instruments.

Application |

NDT Technology |

Product Recommendation(s) |

| Generic Weld Quality Inspection | Eddy Current & Ultrasound | MIZ-21C – Affordable and advanced handheld |

| Surf-X Flexible Array Probes | ||

| TOPAZ Family of Instruments | ||

| WELD Crawler | ||

| Corrosion Detection | Ultrasound | TOPAZ Family of Instruments ElbowFlex Scanner |

| NDT Sweeper Scanner | ||

| NDT PaintBrush Scanner | ||

| Surface Inspection | Eddy Current | MIZ-21C – Affordable and advanced handheld |

| MIZ-200 – High-performance instrument | ||

| Surf-X Flexible Array Probes | ||

| Thickness Mapping | Ultrasound | TOPAZ Family of Instruments ElbowFlex Scanner |

| NDT Sweeper Scanner | ||

| NDT PaintBrush Scanner | ||

The flexible and versatile NDT instruments, scanners, and probes from Zetec provide ideal solutions for industries to meet their weld inspection and test procedure standards. Easy scanning with complete coverage for varying geometry allows technicians to thoroughly inspect components and obtain accurate results, helping to mitigate risks and improve operations.

Zetec can help you match the right NDT solution for your weld inspection and test procedure requirements. For more information, contact us today.