NDT Bolt Inspection and Thread Testing

Bolts, fasteners, and thread are used in almost every industry including aerospace, oil and gas, manufacturing, and construction. Although a small-sized component when compared with the entire asset, bolts and the immediate areas surrounding them play an important role in ensuring the integrity of an entire structure. The non-destructive testing of certain bolts and fasteners is an essential process to ensure there are no anomalies that may pose threat to the successful construction of these structures and safe operation within the industries that rely on them.

Bolts are types of threaded fasteners, mostly made from metals. Depending upon the type of metal, processes used in their manufacturing, and environmental exposure, bolts and the areas around them may be prone to flaws like cracks or corrosion. Inspection before and during use helps to ensure that flaws are detected for secure and reliable fastening.

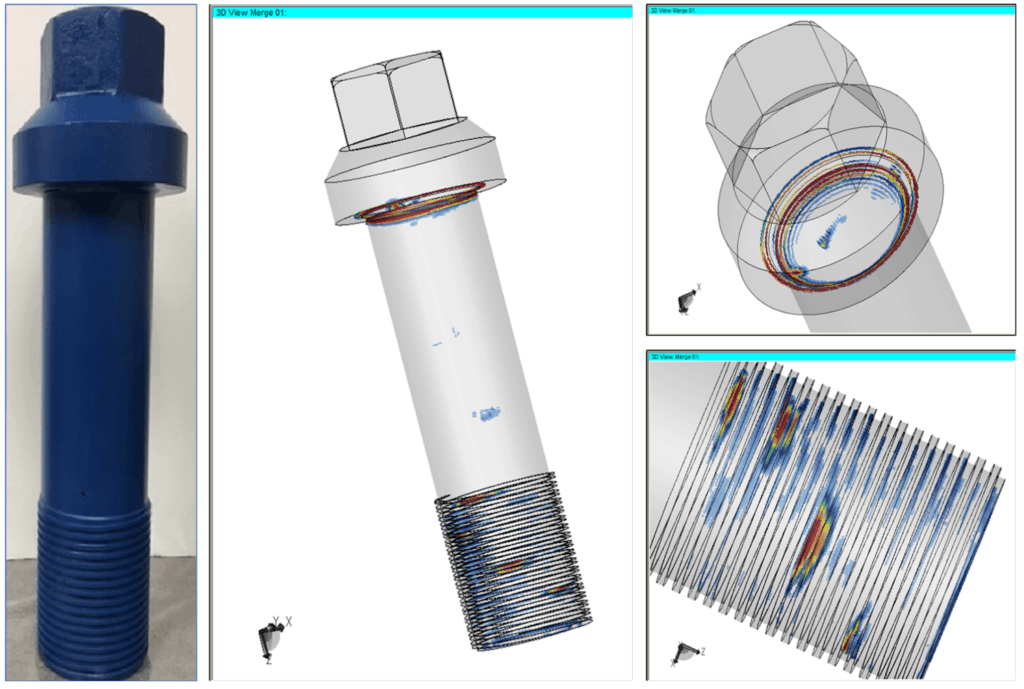

Ultrasonic testing (UT) and eddy current testing (ECT) are some of the most effective and relied-upon methods for small or large bolt, fastener and thread inspections. UT inspection uses high-frequency ultrasonic sound waves to detect anomalies in the component. Similarly, ECT inspection uses an electromagnetic field for sensing the irregularities on or near the surface. An advanced NDT instrument can:

- Accurately discover minute flaws.

- Detect surface and subsurface fatigue damages.

- Perform bolt inspection without the need to remove the fastener.

- Provide thread verification quickly.

- Display 2D/3D scans to study the flaw.

- Provide flexibility to inspect hard-to-reach corners.

Bolt Inspection Resources and Applications

Non-destructive testing is used for bolt, fastener and immediate surface area inspection as well as thread testing across many industries for quality control and safety purposes. We have compiled a few resources that explain how different testing instruments and methods aid in thorough bolt inspection.

- Riser Bolt Inspection (Application Solution)

- Countersink Fastener Inspection (Application Note)

- Piper Aircraft Bolt Hole Inspection (Application Note)

Product Recommendations for Bolt and Thread Inspections

Zetec offers a wide range of NDT instruments for bolt inspection to meet your industrial specification. Depending upon your application, eddy current and ultrasonic testing may be well suited to achieve the best results. To assist in your selection of UT and ECT instruments, we have compiled a list of our advanced bolt inspection NDT solutions.

Application | NDT Technology | Product Recommendation(s) |

| Bolt, Bolt Hole and Fastner | Eddy Current & Ultrasound | MIZ-21C – Affordable and advanced handheld Surf-X Flexible Array Probes InSite HT & CT Instruments TOPAZ Family of Instruments |

| Thread Verification and Inspection | Eddy Current | MIZ-21C – Affordable and advanced handheld InSite HT & CT Instruments |

Advanced NDT instruments, scanners and probes can help technicians perform reliable, accurate bolt, fastener and thread inspections across various industries.

Zetec can help you match the right NDT instruments for your bolt inspection needs. To learn more, contact Zetec today.