Ultrasonic Testing of Anchor Bolts: A Guide

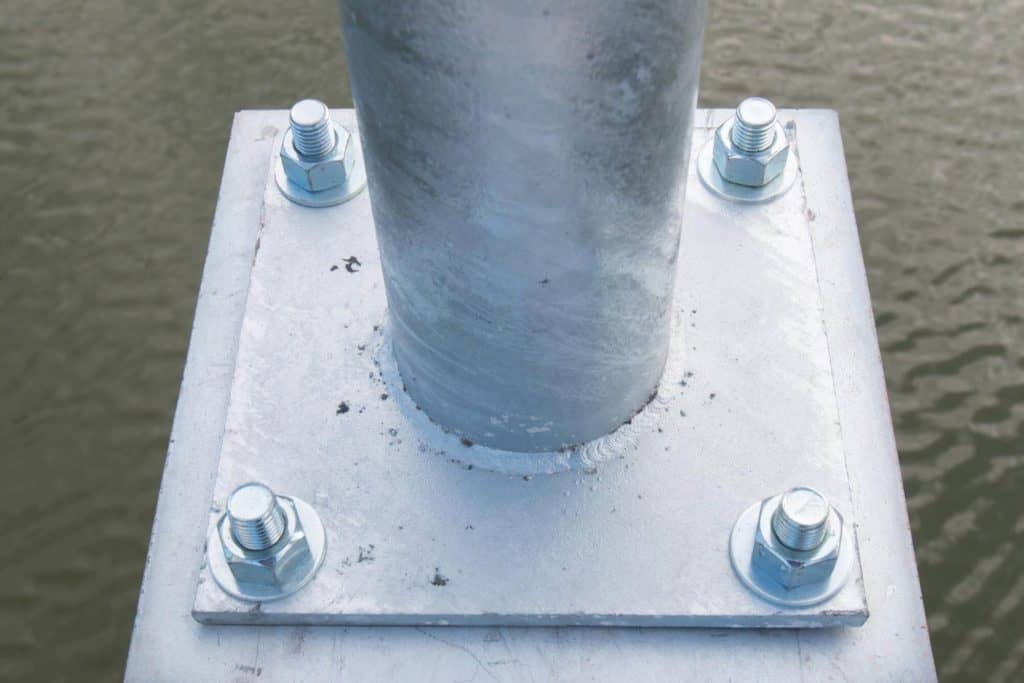

Industrial anchor bolts are typically exposed to rough conditions and subject to intense pressure while still needing to maintain performance integrity. Because of this, testing is so important.

When testing anchor bolts, many manufacturers rely on non-destructive testing (NDT) solutions. NDT helps detect flaws in an anchor bolt both before and after implementation, allowing manufacturers and users to avoid costly damage.

While there are many types of non-destructive testing, ultrasonic testing of anchor bolts gives manufacturers the flexibility, durability, and most importantly the accuracy they need to feel confident in their inspection.

Why NDT for Anchor Bolts is So Important

Anchor bolts, along with rods help to attach items of great weight and importance. In many cases, subsurface damage is likely hidden. That damage can appear and spread fairly quickly.

The greatest enemy of anchor bolt performance is corrosion. Humidity, wind, rain, snow, sun, and even conditions inside of a manufacturing plant, can all lead to corrosion. The tiniest amount of corrosion can spread, eating away at the vital foundation.

Anchor bolt testing is critical, both during manufacturing and when they are in use in the field. Being able to test quickly and efficiently in challenging conditions is key to successful maintenance. That’s where ultrasonic testing comes into play.

Why Ultrasonic Testing of Anchor Bolts Works Best

There are many challenges associated with the testing of anchor bolts. Those challenges may involve:

- Some or all of the anchor bolt and rod being hidden;

- Damage below the surface;

- Hundreds or thousands of anchor bolts that need to be inspected; and

- The need for accuracy to be complemented by speed and efficiency.

The last point is especially crucial. When there are inspections to be conducted, in challenging conditions, you want a solution that is fast, easy-to-use, and effective. The right ultrasonic testing equipment can be the best solution. By using a high-frequency sound wave to discover and map anomalies, ultrasonic testing (UT) shows the minutest damage on and below the surface. Technicians can get a full 3D picture of an anchor bolt, detecting where damage has occurred with precision.

The benefit of ultrasonic testing for anchor bolts is that there is no one set solution. There’s only the right combination of tools for your specific needs. An efficient UT solution involves instrumentation, scanners, and/or probes, tied together by software. Different jobs will require different types of ultrasonic testing scanners. In a job such as anchor bolt testing, a manual 2D encoded ultrasonic scanner is possibly your best bet, especially when scanning irregularly-shaped objects in hard-to-reach areas.

A manual 2D ultrasonic scanner should be:

- Easy-to-use

- Lightweight

- Ergonomic

- Small

- Able to scan in difficult-to-reach areas

These capabilities are extremely important. Because human guidance is needed to wield the scanner, this likely means the technician will be lifting and scanning, at odd angles, and in tough conditions. Accuracy is key and exhaustion is the enemy. The scanner should be able to make the technician’s job easier.

Ultrasonic testing will require an ultrasonic probe. There are many kinds that are designed for specific applications. The right probe should be accompanied by intuitive instrumentation that collects the data and uses proven software to draw the image and analyze that data. The instrumentation is the brains behind the tool, and using it correctly ensures accurate readings.

What makes instrumentation work best?

- Temperature operating ranges

- Fast processing capabilities

- Class-leading, industrially-proven software

- Durability

- Ease of use

- Ease of carry

Solutions like TOPAZ16 or TOPAZ32 are ideal for the ultrasonic testing of anchor bolts because they are easy-to-use, accurate, and efficient. When time is money, and mistakes can cost a lot of money, there’s no excuse for using anything but the solutions that work best in your field.

The Power of Flexibility During the Ultrasonic Testing of Anchor Bolts

Anchor bolts, by definition, shouldn’t be flexible. They need to be sturdy. They need to weather tough conditions and stand the test of time. But your UT solutions? Those should be flexible.

Probes, scanners, and instrumentation all depend on each other and work as a coherent system. You deserve a partner who can help you pick out the right solution, one that works for your industry and specific needs.

Ultrasonic testing of anchor bolts is crucial to fighting corrosion, protecting investments, and defending infrastructure. Whether testing for tiny flaws during manufacturing or for damage that occurred in the field, ultrasonic testing is the solution for your anchor bolt inspection needs.

Zetec is a major provider of ultrasonic testing solutions for anchor bolts in any industry. Contact us today to get the best equipment and the top solutions for anchor bolt inspection.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.