How NDT Scanners Simplify Complex Inspections

Every infrastructural operation has to deal with material components in a variety of shapes and sizes. Some components are straight and simple, while others involve complex geometries, such as in pipelines—where there are straight running components as well as curved parts with elbows and offsets. To verify the safety of these components before or during use, non-destructive testing (NDT) is essential.

Advanced NDT tools and technology allow inspectors to thoroughly inspect and identify the properties and weaknesses within the material being tested. But when it comes to inspecting complex geometry like curves, it can be difficult for all of the same tools to accurately analyze the results through the curvature. Specialized equipment could be needed. This concern is addressed by advanced ultrasonic testing (UT) scanners and probes that are flexible to adjust according to the curves of pipe elbows, as an example, and provide accurate results.

The Advantages of Mobile Ultrasonic Scanners in the Inspection of Complex Geometry

Industries require non-destructive testing for inspecting a wide range of small or large components. When considering large manufacturing facilities or oil and gas pipelines, the inspection may be large-scale or expand for miles. In these industries, challenging components that require inspection are often offset and elbow pipes. If a flaw within these components goes undetected, it can lead to operational and safety risks.

The most prominent types of flaws in offset and elbow pipes include corrosion pitting or fluid-induced corroding. In these cases, spot inspection or the more conventional scanning may not be effective for flaw detection.

Instead, technicians should rely on more flexible, portable, and mobile NDT scanners to inspect the component accurately and efficiently. The ability of the same inspection probe to conform to varying geometries allows technicians to effectively inspect straight as well as curved

surfaces without having to stop and install additional equipment. With magnetic wheels, technicians can easily keep the NDT scanner on the inspection track, also along the curvatures, facilitating continued imaging for complete coverage.

Advanced Features of Modern Flexible Probes

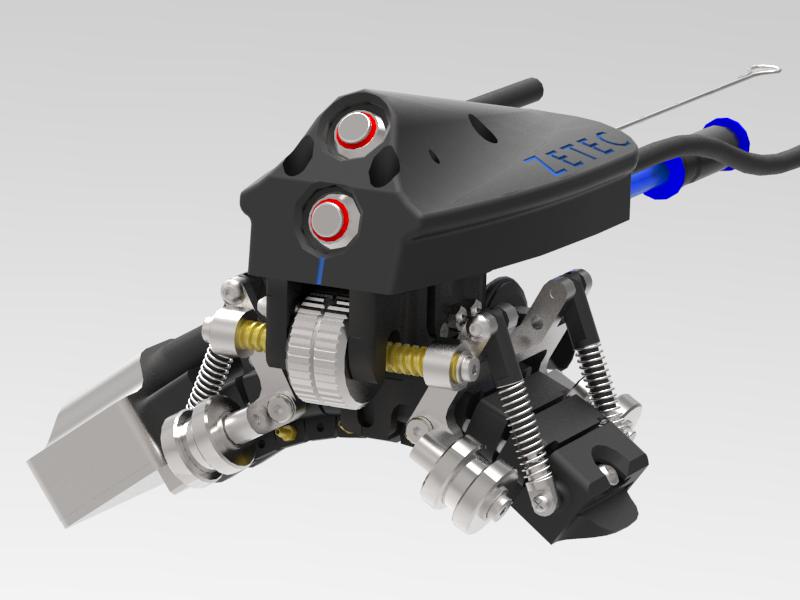

Achieving comprehensive and high-quality inspection coverage requires NDT scanners and probes with flexible and versatile capabilities. Ultrasonic testing technologies such as Zetec’s Weld Crawler, ElbowFlex Scanner, and NDT Sweeper are ideal solutions for detecting flaws through the maneuvering of probes around the inspection piece of complex geometries. These NDT scanners assist in flaw detection with characteristics such as:

- Ease of Use: The capability to easily conform to complex geometry makes it easy for technicians to use the probe in a single run, without having the need to stop and adjust. This helps in providing 100% coverage while saving inspection time.

- High-resolution imaging: The inspection is only effective until the results obtained can be analyzed for accurate flaw detection. High-resolution C-scan imaging during the inspection process allows technicians to spot even minute details through fast and easy analysis, increasing operational safety.

- Flexibility: Zetec’s NDT scanners and probes can function at varying operating conditions, calibrate to circumferential changes with ease, and provide on-the-fly inspection parameter optimization. This flexibility ensures time efficiency and accurate inspection.

NDT Scanners: Solutions for Easy and Complete Coverage

The ultrasonic NDT scanners and probes from Zetec provide a flexible, versatile, and reliable solution for the inspection of complex geometries. In the inspection of the weld or metallurgy of a metal component, these probes offer high-resolution imaging for identifying the type of defects. The flexibility of the scanners ensures the curved surface along the elbows or offsets of the pipeline are thoroughly inspected to determine weld integrity, wall thickness, inclusions, and other flaws. The advanced features of these scanners and probes allow industries to meet their complex NDT inspection demand for improved quality and safety.

Zetec is a leading provider of high-performance NDT solutions for the inspection of industry pipelines using advanced ultrasonic inspection technologies. Our flexible NDT scanners and probes support precision inspection along the varying curvature of the inspection piece. Contact us today to learn more about our NDT solutions.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.