Efficient High-Speed Ultrasonic Rail Testing Requires Powerful, Portable NDT

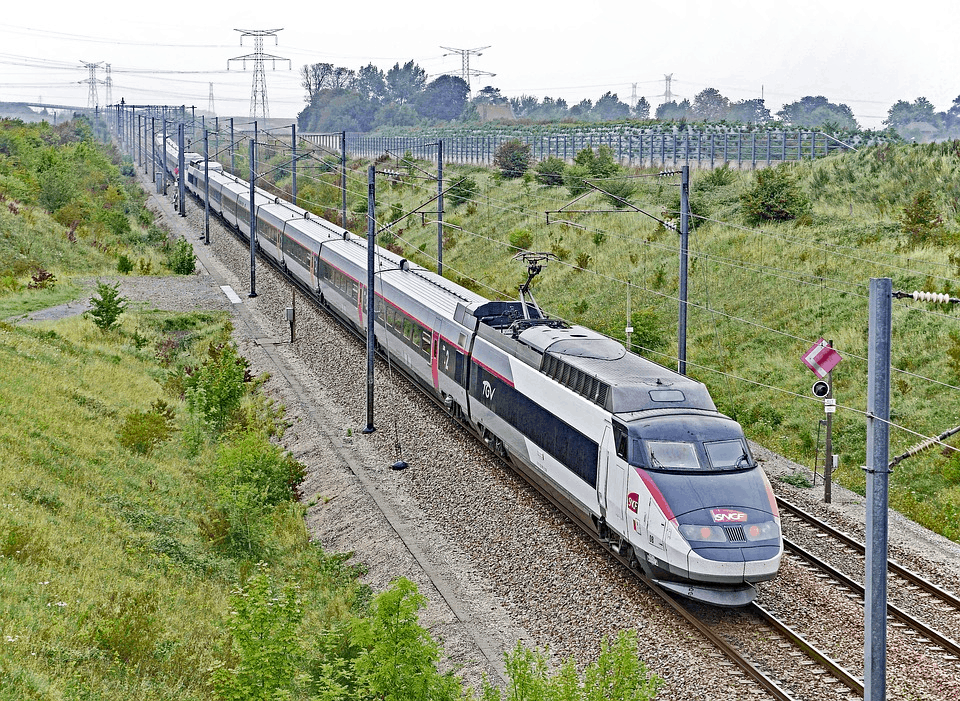

High-speed rail travel is one of the safest travel methods currently available to the modern public. However, poor maintenance and monitoring can place passengers and crew members in danger, which is why high-speed ultrasonic rail testing is crucial. Deteriorating infrastructure could lead to hazards as derailment or track defects.

However, technicians cannot commence a satisfactory testing regimen without a few notable tools in their arsenal—in particular, portable and powerful nondestructive testing (NDT) equipment. Ultrasonic technology is a vital NDT technique for high-speed rail testing, with specialized phased array ultrasonic technology (PAUT) being among the most reliable and efficient inspection methods currently available.

The Advantage of PAUT for Rail Testing

The railway industry will undergo an increase in traffic, including heavier loads, which is why efficient inspection strategies are more important today than ever before. PAUT can help analysts find more defects within rail infrastructure in less time by fostering added scanning angles, allowing users to customize the wave beam when necessary. Beam customization grants users the ability to tailor the scanner according to the geometric patterns of railing infrastructure, producing a more comprehensive outlook of the design profile. Additionally, PAUT scanning conforms to complex design forms, such as railing heads, which is a prime area for flaws to develop.

PAUT is adept at detecting the following deviations within rails:

- Transverse Cracking

- Gauge corner cracks

- Squats

PAUT offers the added benefit of beam steering, which provides an efficient mapping schematic of testing objects at various angles. PAUT also permits multiple angles from a single probe, allowing analysts to spend less time on probe changes and more time on finding additional flaws. Best of all, PAUT’s single-probe detection prowess enhances the probability of detection. With that, the power of PAUT is most effective when the instrument is portable.

The Importance of Portable UT Equipment

Railcar UT inspections are vital tools that can detect defects in a shorter time frame. However, analysts need portable UT equipment to further examine deviations detected by the railcar at any moment. According to the Federal Railroad Administration, rail track flaws are the second leading cause of railway mishaps in the United States. A UT instrument should be portable enough to easily carry from one section of track to the next—wherever flaws have been detected or are suspected to have formed. Portability permits the necessary convenience that reduces inspection times and allows users to move on to the next testing procedure more promptly.

Combating Coarse Grain Challenges with 2D Matrix Array

NDT technicians may encounter manganese steel sections at various locations of railing infrastructure. The grain coarseness and attenuation can complicate matters during the inspection process, resulting in incomplete data. Analysts may also encounter harsh grains in gas pressure rail welds. For tougher welds with high grain levels, instruments with 2D matrix array capabilities can expose irregular flaws with greater accuracy and dispel worries about skewed data or distorted beams.

Using lower frequencies (1.5 MHz to 3.5 MHz), the 2D function counters propagation issues caused by the coarse grain content, allowing for more detailed and accurate readings than would otherwise be attainable with UT or other NDT equipment.

UT Software Considerations

Hardware is important, but software is an important consideration as well when choosing high-speed ultrasonic rail testing solutions. Analysts need state-of-the-art software that streamlines the inspection process by displaying data on a simple, easily navigable interface and providing precise data analysis that paints the clearest picture possible of the railing in question. High-quality software can also enhance PAUT inspection processes in the following ways:

- Reduced Inspection Time: Post-processing capabilities help eliminate the need for rescans.

- Improved Detection: The addition of bipolar pulsers allows analysts to penetrate thicker welds during the inspection process.

- Multipurpose Functionality: Offers combined Time of Flight Diffraction (TOFD), phased array, and Total Focusing Method (TFM) capabilities for even greater accuracy.

In short, utilizing cutting-edge software is key to ensuring peak performance and efficient inspection processes.

Taking High-Speed Ultrasonic Rail Testing to the Next Level

High-speed railways present a number of inspection challenges due to the materials and complex geometries involved. The most effective way to overcome these challenges and ensure the highest level of railway integrity and safety is to utilize a combination of the right techniques and the best of what today’s NDT manufacturers have to offer. For high-speed rail testing, few technologies come close to the speed, accuracy, and detail that high-quality PAUT software and instrumentation can provide. Choosing powerful, portable PAUT equipment ensures the highest level of efficiency and offers results you can count on—so that your passengers know they can always count on you.

Zetec manufactures top-quality NDT solutions that high-speed railway inspectors can depend on for fast, accurate results. Contact us today to get up to speed on our latest PAUT equipment and software.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.