A compilation blog page that provides a short summary of the value of ultrasonic inspection techniques in the inspection of

Read More

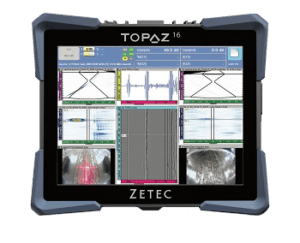

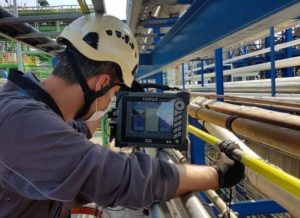

This post will discuss the importance of portable NDT equipment for use in petroleum, routine aerospace inspection, and other fields

Read More

Butt welds are flat surface to flat surface welds, including the flat facing surfaces of pipe welds. When welding HDPE

Read More

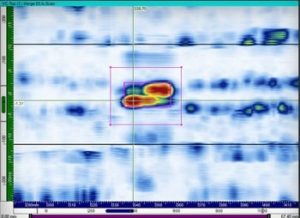

This blog post will discuss the importance of data interpretation in conducting NDT inspection quickly, and producing results that can

Read More

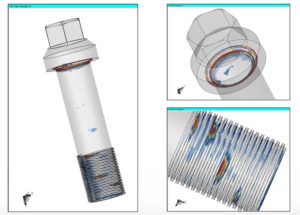

Interpreting ultrasonic testing can be enhanced with 3D modeling and tracing ultrasonic rays penetration and reflection within the volume of

Read More

In advanced industries like aerospace, multilayer composites and laminates of metals and ceramics are common in high-performance parts. It is

Read More

Nondestructive testing (NDT) is an accurate, efficient, and vital method of protection for industries across the globe. NDT allows manufacturers

Read More

Ultrasonic inspection is widely used in industry for quality control and inspection of infrastructure. This compilation blog will gather QC

Read More

This post will be an honest discussion regarding UT vs radiography testing using x-rays bearing in mind that many of

Read More

Acoustic modes are a type of crystalline lattice (found in metals) that allow long wavelengths to propagate like acoustic waves

Read More