Enhancing Phased Array Ultrasonic Testing Interpretation with 3D Environments

In recent years, phased array ultrasonic testing (PAUT) has advanced technologically and has helped industries deliver quality products. This non-destructive testing (NDT) technology has been able to improve the accuracy and efficiency in a safe and efficient manner—attributes greatly desired by industries like aerospace, automotive, petroleum, and power generation that have high-stake safety needs. For this very reason, innovation is a constant need for NDT.

In inspection technology like PAUT, 3D modeling and analysis is a relatively new concept. However, the benefits of simulation, control, coverage, and accuracy make 3D phased array ultrasonic interpretation a desired capability.

How 3D Analysis Facilitates Phased Array Ultrasonic Testing Interpretation

3D analysis software has long been used in many industries for design, calibration, and manufacturing. But the technology has not been so prevalent when it comes to 3D simulation for NDT. Image processing has traditionally been done with 2D software packages. In a 3D virtual environment, it is now possible to interpret the geometrical aspect of the component and flaw. Inspection techniques like phased array ultrasonic testing can especially be leveraged to its full potential with 3D interpretation for inspection of complex geometrical components.

Phased array ultrasonic testing has been used in industries for its capability to utilize multiple transducers in a single assembly to inspect a component in a controlled and speedy manner. With individual control of the transducers, PAUT probes have been able to collect data and present an accurate picture of the existing flaws and detect the material quality. Software like Zetec’s UltraVision facilitates a 3D environment where the creation of the actual inspection configuration is possible with the possibility of ultrasonic ray penetration and reflection tracing.

3D Ultrasonic Ray Tracing

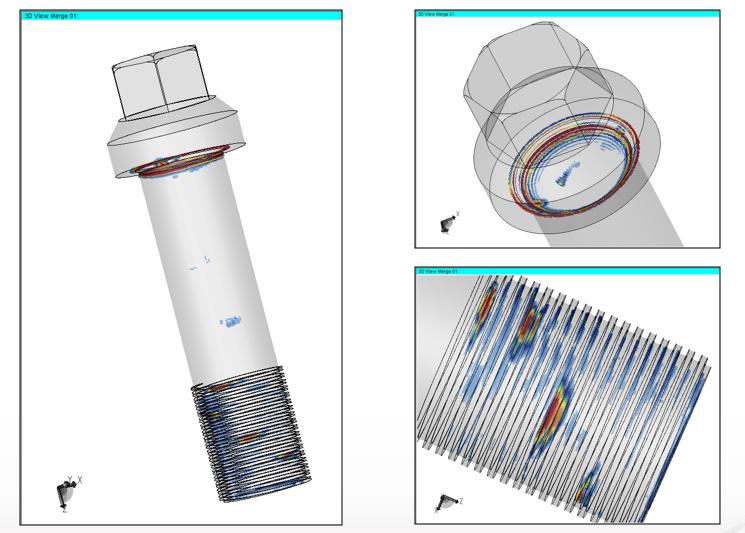

In a 3D environment, it is possible to import a CAD model of the inspection component or create one with the help of ultrasonic testing data. UltraVision provides a 3D ray-tracing tool that can utilize this 3D model to accurately analyze the probe location and beam angle to accurately assess: 1) positioning and characteristics of the flaw and 2) travel time of the reflected beam. In phased array ultrasonic testing interpretation, the 3D ray tracing can graphically represent the array of rays and their interaction with the flaw.

The 3D environment also facilitates the provision for scanner simulation whereby multiple probes can be analyzed to identify the suitability of the inspection of a particular component. In combination with a 3D ray-tracing tool, technicians can create coverage maps and identify probe and beam trajectory to validate and optimize the testing and interpretation of geometrically simple or complex components.

3D Visualization

3D visualization plays an important role in ensuring inspection accuracy and speed. With a 3D view of the component model, technicians can accurately locate and characterize the flaws in the most efficient way possible, which is especially beneficial in complex geometries. The data easily collected from the NDT scanners can be plotted or overlapped with the specimen model in the 3D environment for accurate orientation and positioning of the flaw. With easy visualization of the flaw, the inspection process can be completed in a fast and efficient manner.

| Watch: Learn how the 3D environment on UltraVision software supports and adapts to a wide range of probes to improve the efficiency of inspection. |

3D Solutions for Enhanced Phased Array Ultrasonic Testing Interpretation

With industrial interest in the 3D work environment for NDT solutions on the rise, Zetec’s proven UltraVision software facilitates inspection enhancement with features like 3D simulation, 3D ray tracing, 3D data visualization, 3D model generation, and real-time imaging.

With 3D, asset teams can not only improve their phased array ultrasonic testing interpretation ability but also improve coverage and validate inspection approaches for enhanced inspection design and implementation.

Zetec’s advanced phased array ultrasound testing equipment provides a 3D environment for enhancing the accuracy and efficiency of your inspection needs. To learn more about our NDT solutions, contact us today!

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.