How NDT Imaging Software Makes the Detection Difference

Non-destructive testing (NDT) has been established as a standard for flaw detection in many industries. With the ability to inspect welds and other structures—material surface, subsurface, or volumetric—for discontinuities or damages, industries like aerospace, automotive, oil and gas, and manufacturing have been able to ensure the safety of the products and operations. Many inspection methods have been utilized, and various instruments and probes have been developed to achieve the best inspection result. However, the use of intuitive NDT imaging software is equally as important. With the software’s clear image capture and display ability, technicians can quickly and easily interpret the result to identify the best possible solution.

NDT Imaging Software for Accuracy in Flaw Detection

Eddy current testing (ECT), ultrasonic testing (UT), or any other NDT method, can truly be effective when the data captured is interpreted with accuracy. NDT imaging software allows the data captured during the inspection process to be analyzed and digitized in real-time or for offline interpretation. The software can also be used to facilitate easy integration with other NDT products to effectively scan the component and display signals for potential flaw detection.

Having a clear and easy-to-use NDT imaging software allows technicians to easily understand and set up the inspection system. The captured data can then be processed and the output analyzed regardless of the technician’s skill level. The functionalities of NDT imaging software provide the following benefits:

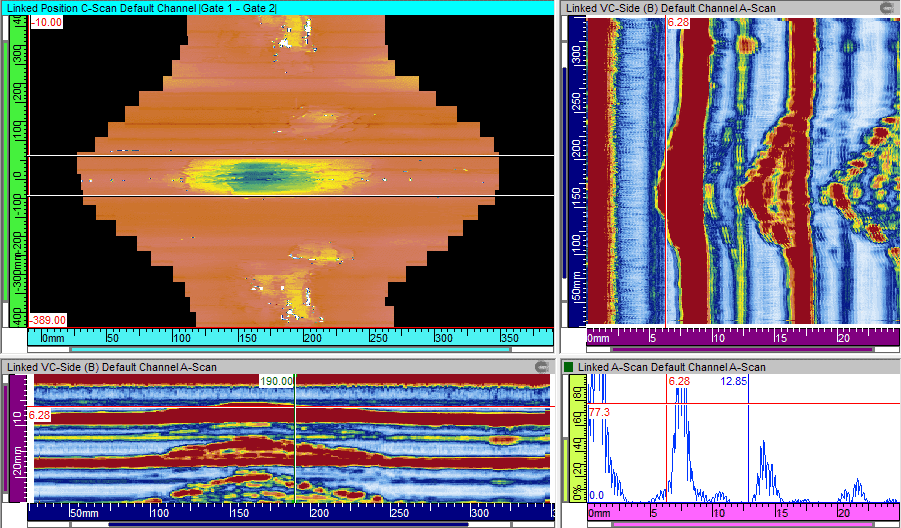

Accurate Flaw Identification: NDT imaging software can allow the comprehensive display of acquired data in a 2D or 3D format. Analysts can accurately analyze the acquired A, B, or C-scan imaging for in-depth identification of flaws including cracks, corrosion, inclusion, or other discontinuities.

Workflow Optimization: The software allows for easy planning, scheduling, data acquisition, and analysis capabilities facilitating an efficient inspection process. Some software also provide auto data acquisition and analysis, allowing technicians to focus on other more important tasks, thus, improving productivity.

Faster Inspection: With each inspection and optimized workflow, data can be collected at a much faster rate. Data analysis parameters can be set up upfront. The output can also be received in a relatively faster time. This function can help minimize downtime and improve productivity and component reliability.

NDT Imaging Software Features

Output may vary depending upon the various features of the NDT imaging software. Here are some features that industries look for to determine inspection and analysis suitability.

- Data Merging: In some inspection processes, data capture may not be possible with a single scan. In such a case, software such as UltraVision with the ability to merge multiple C-scans into a single file can be a useful feature. Each individual scan can be stitched and manipulated to ensure proper alignment and display in a single interface. This ability helps in accurate detection and determining the size of a flaw.

- 3D Data Analysis: Software such as UltraVision provide a 3D module where all the data and scans can be acquired and presented in a 3D environment for all simple and complex geometrical components. The visual analysis of the surface condition in a simulated environment facilitates improved flaw detection accuracy.

- Historical Data Comparison: This capability allows users to compare current and previous inspection data over time. Any changes in the signals can be easily analyzed to identify any new or growing flaw formations.

- Online or Offline Data Analysis: Depending upon the application, industries may seek online or offline inspection and analysis ability. This increased computing and data processing ability has enabled advanced software to perform real-time data analysis for critical inspection tasks without compromising image display resolution.

Leveraging Software Capabilities for Improved Inspection

With new and improved capabilities, NDT imaging software is becoming more user-friendly. It is now possible to automate elements of the data acquisition process, analyze data in real-time, and visualize data in a 3D environment, without compromising the quality of the output. Industries can leverage these benefits of NDT imaging software to acquire advanced flaw detection ability while improving their productivity and cost-efficiency.

Zetec offers a wide range of NDT imaging software solutions for industrial UT and ECT inspection requirements. For more information on our NDT software and instrumentation, contact us today.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.