- Home

- Products

- Eddy Current

- ET Software

- UltraVision ET

OVERVIEW

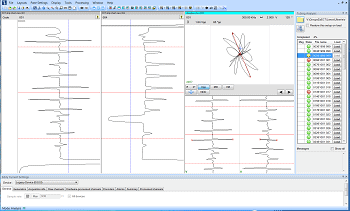

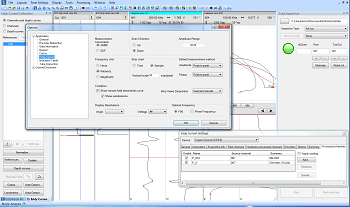

UltraVision ET leverages the simplicity of the industry proven UltraVision software interface for ultrasound and applies it to the eddy current heat exchanger (HX) tubing and surface inspection process. It is also designed to deliver an easy platform transition and a better user experience for former Multiview users.

Users will enjoy easy job set-up and technique configuration for faster inspections. The intuitive user workflow enables the user to easily step through a Bobbin, RFT, or MFL for heat exchanger tubing and a range of array, standard and customized applications dedicated to surface inspections. UltraVision ET provides a powerful platform for eddy current data acquisition, analysis, and reporting in one simple, easy-to-use application.

Powerful eddy current solution for heat exchanger tubing inspections

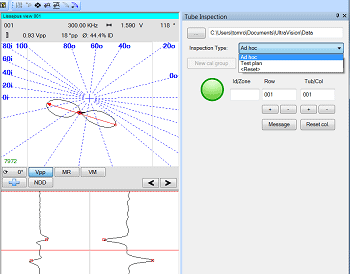

When Ultravision ET software is used with the Zetec MIZ-200 Eddy Current instrument and bobbin probes, it creates a powerful solution for the BOP and oil & gas markets. Zetec delivers some of the highest performance, most dependable and fastest heat exchanger inspection solutions in these industries.

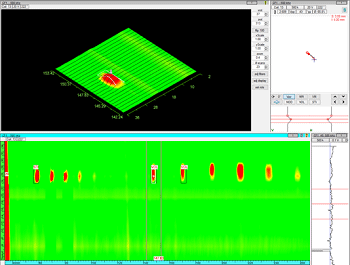

Powerful eddy current array solution for surface inspections

UltraVision ET is the only software in these industries which supports conventional pencil and Surf-X array probes for surface applications from a handheld MIZ-21C instrument for data readback and accurate post data analysis. It also supports the MIZ-200 instrument for standard and customized surface array inspection solutions, as well as conventional tubing inspections.

Powerful reporting capabilities for tubing and surface inspections

UltraVision ET provides a powerful reporting user experience with its own reporting capabilities and with support for complementary, well-known reporting software programs such as CARTO, used mainly for tubing applications.