How TOPAZ64’s TFM Calculator Helps Operators Maintain Code-Compliant Amplitude Fidelity

By Guy Maes, Zetec Sales Engineer Director – UT

Advanced focusing techniques are valuable tools in the phased array toolkit. They can improve the resolution of flaw images and increase the coverage of ultrasonic inspections.

The new Mandatory Appendix XI in the latest edition of the ASME Boiler & Pressure Vessel Code (BPVC) Section V outlines requirements for the use of Full Matrix Capture (FMC), raising the profile of FMC and advanced algorithms like the Total Focusing Method (TFM).

In addition to setting calibration standards and other rules for code compliance, Appendix XI requires a signal amplitude fidelity threshold of 2 dB. The amplitude fidelity represents the maximum possible amplitude error for a TFM frame according to the Nyquist or sampling theorem, a principle that engineers follow in the digitization of analog signals.

UltraVision Integration

The amplitude fidelity for a given inspection configuration depends on the probe frequency and wave mode, the material velocity and the resolution of the TFM frame.

The onboard UltraVision Touch software for Zetec’s TOPAZ family of integrated phased-array instruments includes a TFM Calculator that helps the operator select an adequate and code-compliant frame resolution. On the instrument screen, the depth and width of the individual pixels is shown in wavelength units. The user interface also automatically shows the calculated value of the amplitude fidelity.

Influence of amplitude fidelity on TFM image quality

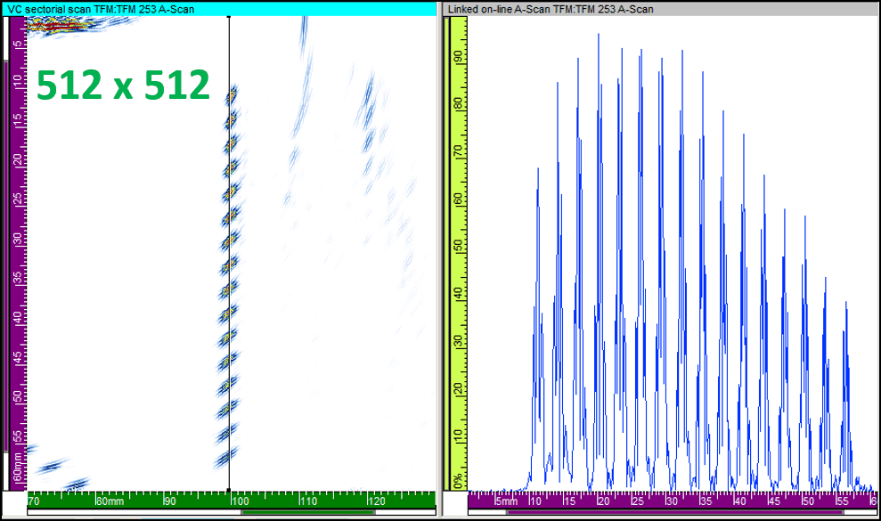

As an example, let’s look at a high-resolution TFM frame, 512 by 512 pixels, generated with 64 probe elements. We can see the TFM frame on the left side of the image and the amplitude depth curve on the right. This curve is like the A-scan signal of a virtual 0-degree probe in each horizontal position of the TFM frame. The different echoes represent the responses from the side-drilled holes in a calibration block, and we can see a regular sensitivity distribution.

For this TFM frame, the pixel size is one-tenth of a wavelength and the amplitude fidelity is less than 0.5 dB—well under the threshold according to Mandatory Appendix XI.

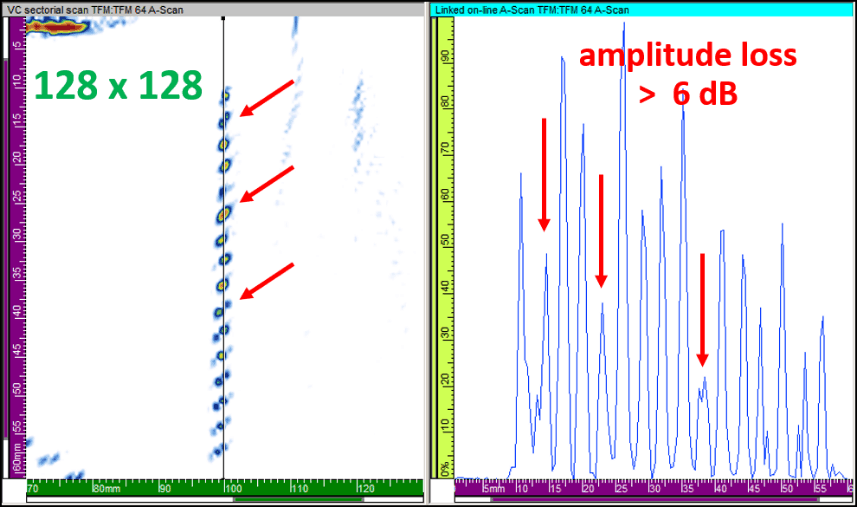

If we change the frame resolution to 128 by 128, the pixel size will become as large as 0.4 of a wavelength and the amplitude fidelity will largely exceed the code-compliant threshold of 2 dB.

The TFM image with a 128 by 128 resolution has a very different aspect—it looks pixelized. Also, the A-scan signal on the right shows irregular amplitudes for the echoes from the reflectors.

And if we were to move the probe very slightly on the calibration block—actually less than a millimeter—we would observe random and important variations in the echo amplitudes, as if some reflectors are disappearing and reappearing.

An actual inspection with these parameter settings would be very unreliable and could leave real flaws undetected, and this is exactly why codes have introduced the amplitude fidelity parameter.

For more information

Expert guidance and the right ultrasonic tools are extremely valuable in helping NDT technicians demonstrate code compliance while maximizing the efficiency and quality of an inspection.

For more information, Zetec’s webinar on FMC and TFM provides new insights into advanced ultrasonic techniques and their implementation. Available now, the presentation includes a discussion of the benefits of advanced focusing; a demonstration of the new Acoustic Field tool on the TOPAZ family of ultrasonic instruments; case studies on challenging damage mechanisms; and a more comprehensive look at the concepts in this Insight article. Click here to learn more about the webinar.

Zetec is a global leader in nondestructive testing (NDT) solutions for the critical inspection needs of industries the world counts on every day. To learn more, contact Zetec today!