Friction Stir Weld Inspection

Inspection Challenges

Friction Stir Weld (FSW) inspections can be challenging and time consuming. It typically requires 3 beam angles for flaws parallel to the weld center line (WCL). Standard solutions use multiple probes, and require each probe to be aligned and calibrated, which can be a long process. Some flaw types (transverse, skewed) are not reliably detected with standard probe design. Additionally, the surface condition and flashing can prevent adequate coverage of the weld area with a contact solution.

Recommended Solution

Keeping total inspection time low is critical for process efficiency. A reliable and efficient inspection solution should include rapid setup, quick calibration and fast inspection speed. The following recommended components and approach achieve the desired results:

- A high-performance phased array ultrasonic testing (PAUT) instrument, either fully integrated and portable, or scalable depending on inspection requirements

- Optimized phased array ultrasonic testing probes for improved detection capability and a reduced number of scanning sequences

- An immersion tank inspection for adequate coupling on the welded surface

- Industrially proven software platform for seamless system integration and efficient data analysis

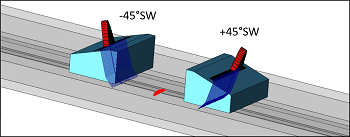

The recommended examination technique for flaws parallel to the weld center line involves linear electronic scanning using 3 beam angles (+45°SW, 0°LW, -45°SW).

All techniques (groups) can be applied in a single

scanning sequence with a volumetric merge of 3 groups for efficient data analysis.

The recommended examination technique for transverse flaws involves linear electronic scanning using 2 beam angles (+45°SW and -45°SW) using probe inclination in the secondary plane.

All techniques (groups) can be applied in a single scanning sequence (2 probes required) with a volumetric merge of 2 groups for efficient data analysis.

Zetec Products

Zetec offers the optimal solution for this type of inspection challenge, delivering a highly reliable and efficient inspection. The following complete solution kit from Zetec features the necessary components and tools to

confidently perform all the examination techniques in the inspection.

Portable: TOPAZ32 fully integrated PAUT instrument

TOPAZ32 is a fully integrated, high-performance phased array UT device. With a 32/128PR configuration, battery operation and UltraVision Touch software onboard for setup, acquisition and analysis, TOPAZ32 is a complete portable solution for your inspections. Features include:

- Fully integrated unit: from preparation to reporting, TOPAZ32 is the complete solution. With easy setup and onboard analysis, you can reduce the amount of equipment needed to perform an inspection.

- Highly capable: ability to combine phased array and TOFD techniques simultaneously. Furthermore, 2D matrix array probe support is included without the need of any external software.

- Industrially proven: driven by UtraVision Touch on-board software ensuring an efficient inspection workflow

- Highly responsive: multi-touch screen that not only offers high resolution, but also one of the largest display size to instrument footprint ratios in its class.

Scalable: QuartZ PAUT instrument

The Zetec QuartZ instrument achieves an excellent balance between speed, power and flexibility for some of the most complex applications. Features include:

- Parallel firing capability

- High power phased array channels: incorporates real 100 V pulser

- High data throughput: can deliver up to 30MB/s of data throughput making the difference for demanding applications

- UltraVision Classic software: for seamless system integration using multiple units

Optimized PAUT Probe. Features include:

- Optimized 1D linear array probe, 7.5 MHz, 128 elem., with small pitch and adequate elevation

- Capable of generating 0°LW and 45°SW for flaws parallel to the WCL without probe inclination

- Capable of generating 45°SW for detection of transverse flaws (when inclined in secondary plane)

Benefits

Optimized Approach

- Optimized PAUT probe design for improved detection and sizing capability, including transverse and skewed reflectors

- Adequate coupling on an ‘as welded’ surface condition

Performance That is Ready to Go

- High-performance phased array UT units controlled by UltraVision software platform, for setup, acquisition and data analysis

- Simplified calibration and improved repeatability

Scalable Solution to Meet Specific Needs

- From one probe and acquisition unit up to 3 probes and units for 3x reduction of inspection time