Composite Material Inspections – Sensor Networks

Simplifying Complex Composite Inspections

There is no limit to the imagination when you’re designing advanced phased-array ultrasound (UT) probes and wedges. That’s especially true in aerospace, where manufacturers are constantly developing composite materials that are lighter, stronger, and easier to shape into dynamic, high-performance components for commercial and military aircraft.

These components have complex geometries, varying thicknesses, and can incorporate several different types of carbon-fiber reinforced polymers.

The Benefits of Customization

“In aerospace applications, a customized probe can allow for faster, more reliable inspections on otherwise difficult jobs,” said Bruce Pellegrino of Sensor Networks, which produces industrial ultrasonic transducers and tooling for demanding in-situ test and nondestructive testing (NDT) applications. “In fact, the probe can enhance the capability of an advanced multichannel phased-array instrument. But it takes collaboration, communication, and a focus on the customer’s specific needs.”

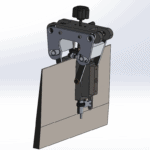

Sensor Networks, an NDT applications engineering company and transducer manufacturer based in Boalsburg, Pa., recently developed a customized UT probe for use with the Zetec TOPAZ32, a fully integrated portable phased array UT device with powerful UltraVision touch software embedded. TOPAZ32 works with a range of standard as well as custom phased-array probes and wedges.

Pellegrino said the combination of Zetec’s TOPAZ32 and the Sensor Networks’ transducer simplifies advanced calibration setups, reduces the time and equipment needed for the inspection, as well as produces detailed reports faster than other instruments on the market.

In this particular application, a Sensor Networks customer wanted a rugged, hand-held UT solution to sector-scan composite engine components for de-lamination, surface and sub-surface matrix cracking, variations in fiber density, and the effects of damage during impact testing.

Zetec Products Make it Possible

“These are relatively large components with curvature changes on both the top and bottom of the part,” Pellegrino said. “TOPAZ32 and UltraVision Software allow us to run two linear arrays, one on each side of the component, and do a through-transmission channel to pick up possible defects. Simultaneously we can run pulse-echo from each probe to gauge the depth of the defect. It delivers accurate, detailed results quickly without requiring a highly skilled technician or expensive robotics.”

A full set of basic and advanced analysis tools (including merge, C-Scan stitching, gate selectors, volumetric contour, and thickness thresholding) are available on-board TOPAZ32 with fully configurable display layouts. Ready-to-print custom PDF reports, including hardware settings, scan plan, and indication information, are generated with a single touch.

“TOPAZ32 and UltraVision Software are state-of-the-art for proven, advanced phased array UT as we know it,” Pellegrino said. “It’s an advantage to be able to do setups in UltraVision where you can bring in a 3D solid of your part, position a probe on the component, and confidently see that your probe is in the right spot. You’re not just filling in text boxes defining your probe and part relationship for the delay law calculations. There’s a lot of visualization in the software that helps ensure that you’re getting sound precisely where it needs to be and helps us maximize the capability of our custom transducer.

“TOPAZ32 is a best-in-class instrument that provides everything necessary for fast, advanced setups, analysis, and reporting in one package,” Pellegrino said. “Our custom transducer will enhance those capabilities. The end result is an integrated solution that simplifies and speeds up complex inspections for the customer.”

Zetec is a global leader in nondestructive testing (NDT) solutions for the critical inspection needs of industries the world counts on every day. To learn more, contact Zetec today!