Inspección de soldaduras axiales en servicio

Inspection Challenges

Inspection of pipe seam welds requires a volumetric NDE inspection method. Traditionally, radiography (RT) is used for manufacturing inspection, but this technology has several drawbacks. In terms of inspection capability, RT is insensitive to mis-oriented planar defects, and doesn’t provide any through-wall sizing capability. There is no immediate feedback to the welders, and RT is disruptive to other activities on the site. With safety regulations getting more and more severe worldwide, the use of radiography is being drastically restricted. Additionally, the cylindrical geometry of long seam welds requires specific attention with regards to examination coverage and flaw positioning.

Recommended Solution & Advantages:

Encoded weld examination using a combination of PA UT and TOFD is a reliable and efficient alternative for RT. It provides excellent inspection capability, with permanent records. In addition, the overall duration of the inspection process is drastically reduced, and ultrasonic examination provides immediate feedback regarding the welding process. The same ultrasonic techniques are also very suitable for in-service inspections.

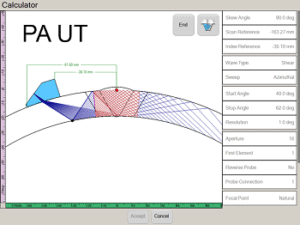

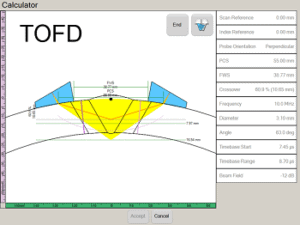

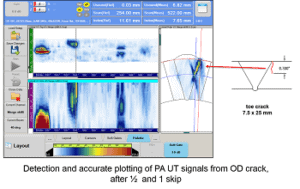

A two-sided phased array UT examination using standard shear wave probes gives excellent detection capability on planar and surface-breaking flaws. The complementary TOFD technique provides good detection on embedded flaws and offers accurate through-wall sizing performance.

Benefits:

Highly effective flaw detection

- The combination of phased array UT and TOFD can detect all welding flaw types, and offers excellent through-wall sizing capability

No disruption to other activities

- As opposed to RT, the phased array UT inspection technology is not disruptive to other activities

Easily adaptable

- The solution is easily adaptable for a wide range of long seam welds configurations

A streamlined inspection process

- Rapid preparation of the setup

- Reliable coverage assessment in the cylindrical geometry

- On-line monitoring of inspection data

- Drastic reduction of rescans due to saturation (16-bit amplitude resolution)

- Accurate positioning and sizing of flaws in Polar View and TOFD View

- Comprehensive reporting, with ensured traceability

Zetec Products:

TOPAZ Fully Integrated, Portable Phased Array Ultrasonic Instruments

- Battery operated, rugged, no air intake

- Rapid and simultaneous two-sided PA UT and TOFD inspection

- Guided set-up of inspection techniques

- Accurate and on-line imaging of inspection data: S-Scan, Dynamic Merge, TOFD

- Capability to record large data files

- On-board software tools for reliable interpretation of inspection data in cylindrical geometry of long seam weld

- Features strong magnetic wheels

- Adapts to long seam welds in tubes down to 6″ NPS

- Carries 4 probes, individually spring-loaded

- Automatically detects encoder parameters

- One-line inspection sequence, manually driven or motorized

- Optional on-board cameras, overseeing and recording the position of 2 probe pairs

Probes and Wedges

- Standard 1D-Linear array probes (e.g. AM-5MHz) with wedges for shear wave generation (e.g. AM-55SW)

- TOFD probes at 7.5 or 10 MHz, with appropriate wedges (45LW or 60LW)