Piper Aircraft Bolt Hole Inspection

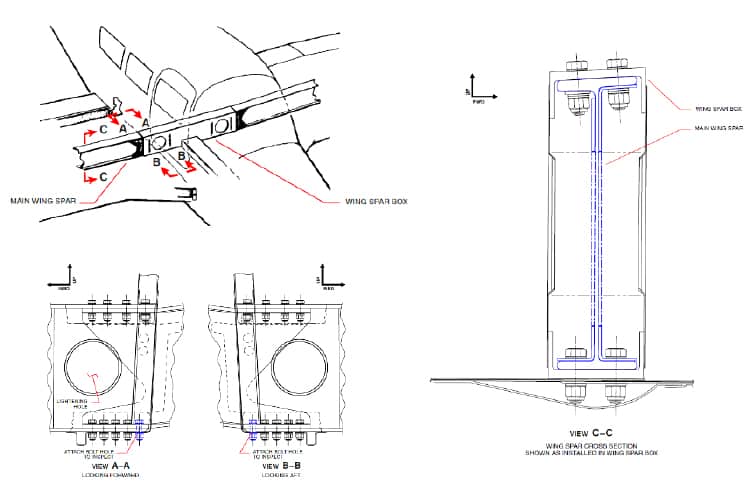

The FAA has issued a new airworthiness directive (AD 2020-26-16) for certain Piper Aircraft models following a fatal crash caused by a wing separation from fatigue cracking on the lower main wing spar cap. Part of the requirements specified in this AD includes inspecting the lower main wing spar bolt holes for cracks. Accordingly, Piper Aircraft, Inc. has issued a service bulletin SB 1345 that provides guidance for this mandatory Piper Aircraft bolt hole inspection.

Inspection Challenges

One of the biggest challenges with this type of inspections is the “multi-layered stack-up” of materials and the need to identify the specific layer where the defect is found. The Piper service bulletin specifies that, “The pass-fail criteria of this inspection is only applicable to a crack in the spar extrusion.” – Piper Aircraft SB 1345. Additionally, it states that any non-crack damage, such as thread marks, gouges, or edge chips, and elongated holes, should be reported to Piper for disposition. Therefore, it is crucial to know in which layer the defect is located, as well as be able to discern between relevant and non-relevant indications.

Recommended Solution

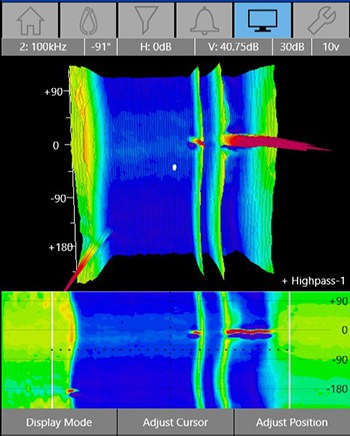

Zetec MIZ-21C with the ZM-5 high-speed scanner can quickly find defects in the bolt hole, as well as identify the layer in which it resides without the need for manual measurement techniques. Multiple frequencies and display modes provide more options for data review and analysis which can improve the inspector’s ability to identify flaws and discriminate between relevant and non-relevant indications. Furthermore, the data can be saved for review at a later time, allowing the inspector to focus on acquiring good data.

Solution Advantages

- Eliminates the need for multiple inspectors

- Identify the layers where flaws are located

- Excellent detection of cracking regardless of orientation

- Leading signal to noise ratio in the industry

- Remarkable c-scan presentations

- High level of detection in a rapid inspection

Zetec Products

MIZ-21C Handheld Eddy Current Instrument

Features Include:

- Approved for the Piper Aircraft bolt hole inspection. The MIZ-21C is an equivalent instrument as specified in Piper SB 1345.

- Ergonomic Design. Small, lightweight and comfortable to handle in tight spaces. MIZ-21C minimizes arm fatigue common with other portable instruments.

- Increase Uptime, Wherever You Go. Features up to a ten-hour battery life so users can operate the unit for an entire shift without recharging. Replaceable batteries support 24-hour operation.

- Data Buffer. Review and save up to 60 seconds (or 10 meters) of data.

- File Manager. Save multiple data files for review at a later time.

- Data Transfer. Transfer saved data through USB.

- Intuitive Touchscreen. Quickly rotate, zoom and pan using the two-finger capacitive display. The onscreen keyboard further increases user efficiency.

- Built for Demanding Environments. Fully sealed and temperature rated for most outdoor conditions. Drop and vibration tested for rugged use.

Features Include:

- Small form factor for getting into tight inspection areas

- Fast inspection speeds with accurate, detailed results

- Designed to provide constant rotation speed under load (600 to 3000 rpm)

- Excellent detection of indications at material transitions and layers