A Flexible Approach to Testing for Flow Accelerated Corrosion

How flexible ultrasonic array probes and scanners make pipe elbow inspections faster and more effective

By Dominic Giguère, Zetec Product Manager – UT Portable Solutions

Phased array ultrasound has become the preferred way to test pipeline wall thickness in pipelines used in oil and gas, petrochemical, power generation, manufacturing and other industrial applications. Yet one type of degradation can still throw inspection teams a curve: flow accelerated corrosion (FAC) in elbows and induction bends.

FAC occurs in pipelines elbows when the movement of fluid causes deterioration on the interior wall. One of the most common examples involves carbon steel or low alloy steel pipe elbows, where the flow of water or wet steam gradually wears away the protective oxide layer on the inside surface of the pipe. The exposed metal begins to corrode, the pipe wall becomes thinner and the risk of metal failure increases.

A number of factors affect a material’s resistance to FAC, including the composition of the steel; the chemistry and temperature of the fluid; and the fluid’s velocity, pressure and turbulence as it moves through the pipe. Particles in the fluid, impingement caused by water droplets in steam or cavitation that occurs when a liquid is subjected to rapid pressure changes can aggravate the problem.

A unique challenge

Large, rigid phased array probes generally are not well-suited for pipe elbow inspections. With a phased array probe, ultrasonic waves enter the material being tested at precise intervals and a set angle. When a wave encounters a defect, some of that energy reflects back and generates an echo. The time it takes for this energy to come back to the probe is calculated and analyzed by the UT instrument’s software and is presented on the display as a C-Scan for the technician to interpret.

It’s difficult for a rigid UT probe to traverse the intrados (inner radius) and extrados (outer radius) of a pipe elbow while maintaining a concentric position so ultrasonic signals can reflect back properly. Technicians can use a combination of smaller probes and wedges to accommodate the convex and concave shapes and variations in material thickness along the pipe elbow, but this adds time, complexity and cost to the inspection.

One approach is to draw a grid on the outside of the pipe to use as a reference for taking spot thickness measurements along the elbow. It’s tedious work, and there’s no code or standard to dictate grid spacing or the number of inspection points. This technique can leave a lot of area in the pipe elbow unchecked and undocumented.

Flexible probes

Flexible ultrasonic array probes and scanners can map both straight and elbow aspects of a pipe and significantly reduce inspection time compared to radiography and conventional UT and grid systems.

Ideal for oil and gas, petrochemical, power generation, manufacturing and other industrial applications, this type of probe has a pliable foam wedge that shapes the array of ultrasonic elements to meet the contour of the pipe elbow. The combination of a flexible array probe and an encoded scanner enhances the technician’s ability to generate a complete map of the inner surface of the elbow and characterize corrosion.

Zetec’s ElbowFlex scanner

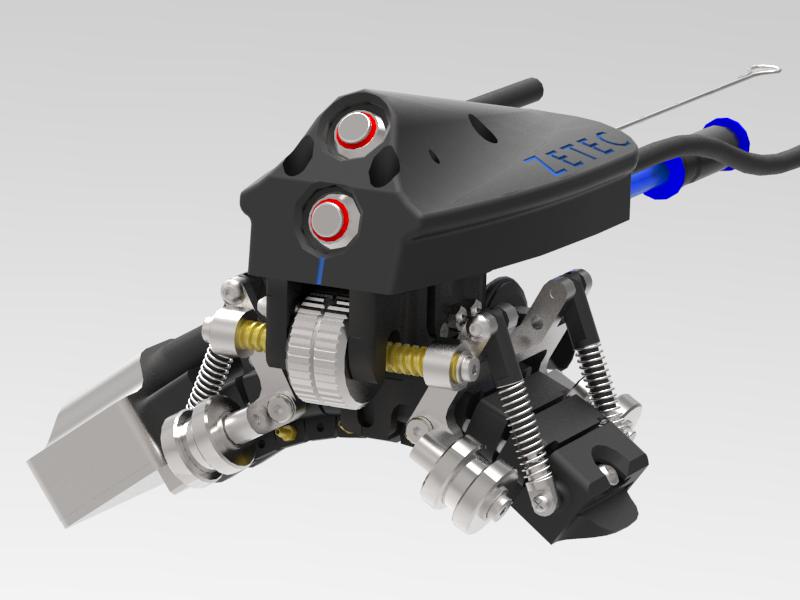

Zetec’s ElbowFlex scanner is the latest and most advanced scanner with a flexible array probe.

Its 1D flexible linear array probe can adapt to the scanned specimen dimension and stay concentric throughout the inspection, providing all you need to cover the full range of elbow diameters in a single probe. At 2.5 pounds, ElbowFlex is easy to handle, with simple button operation and magnetic wheels to keep the scanner firmly in place as the technician guides it along a scan line or the centerline of the pipe. An encoder maps the pipe’s scan axis while the technician can index increments in the second axis with the press of a single button on the scanner.

ElbowFlex is perfect for measuring wall thickness and detecting corrosion on elbows with diameters ranging from 4 inches NPS (4.5 inches) to flat. It uses an Aqualene membrane for coupling in lieu of a water chamber and requires only a thin film of water on the specimen surface. The scanner can also work with standard coupling gel or a mixture of water and gel.

Combined with any instrument in Zetec’s TOPAZ family, ElbowFlex can instantly provide the operator with crisp, high-resolution C-Scan images of corrosion and other damage. It is cost effective, easy to use and saves significant inspection time compared to conventional UT and grid systems.

The complete ElbowFlex kit includes the scanner, flexible probe, Aqualene membrane, encoder cable, wear shoes, shims, tools, carrying case and spare components for consumables.

Zetec is a global leader in nondestructive testing (NDT) solutions for the critical inspection needs of industries the world counts on every day. To learn more, contact Zetec today!