Fast and Accurate Steam Generator Inspections – SNPSC

SNPSC Uses Zetec’s Integrated Eddy Current System for Fast, Accurate Steam Generator Inspections

China’s commitment to nuclear energy has resulted in substantial, nationwide power projects. Mainland China today has 46 reactors in operation with 45.6 GW of installed nuclear capacity and another 11 GW under construction.

The most recent plants to come online are two AP1000 reactors at the Haiyang nuclear power plant in Shandong province. Both units entered commercial service in October 2018, and together they provide some 200 TWh of electricity to the grid each year.

An Integrated Solution

The State Nuclear Power Plant Service Company (SNPSC) was established in 2008 to provide in-service inspections (ISI) and other testing to ensure the safety, reliability, and cost-effective operation of the Haiyang plant.

The organization spent nearly 10 years preparing for the first ISI events at Haiyang Units 1 and 2 and chose Zetec’s integrated eddy current inspection solution for its steam generator examinations. A team of SNPSC technicians completed Unit 1’s steam-generator ISI and the Unit 2 ISI in 12 days, five days faster than planned.

“The AP1000 is one of the world’s most advanced commercial reactors, and steam-generator ISI is the one of the most important and complex inspection activities we conduct,” said Guo Yun, Vice Director/Senior Engineer, Inspection Technology Service Dept., at SNPSC. “The use of Zetec probes, robotics, test instruments, and software as an integrated system helped us optimize planning, calibration, data acquisition, and human exposure to radiation. The technology helped us build on the success of our Unit 1 steam generator ISI to finish five days ahead of schedule on Unit 2 while achieving our goals for safety, accuracy, and plant downtime.”

Intelligent ZR-100 Robotics

The AP1000 steam generator is a vertical-shell U-tube evaporator with integral moisture separating equipment. It provides ALARA access to all tubes with robotics equipment, including those tubes at the periphery of the bundle.

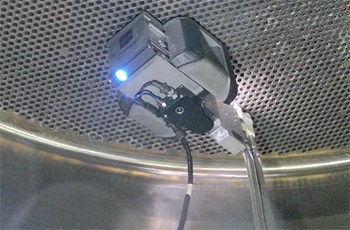

SNPSC used a combination of three Zetec ZR-100 intelligent robots as the probe-delivery platform for its inspection campaigns. The ZR-100 can access more than 200 tubes from a single stance and can traverse the tube sheet at speeds up to 5 feet per minute. Each robot is capable of automatically executing complex steam generator inspections and can coordinate probing with multiple robots within same vessel to avoid collisions.

Due to its smaller footprint, size, and unique crawling motion, Zetec’s ZR-100 provides the ultimate flexibility in reaching all tubes within the tube sheet without human intervention, which minimizes the dose to operators.

A Complete System

To take full advantage of the ZR-100’s automation features, SNPSC operated each robot using the MIZ-80iD integrated acquisition system and Eddynet/AQ software.

The MIZ-80iD is an all-in-one integrated eddy current instrument, probe pusher, and control system. It eliminates complexities associated with deployment, setup, and maintenance, and its ability to throttle probe speed and auto-detect tube ends can significantly reduce probe wear and inspection time. The result is lower cost of operation and higher probability of detection.

This is the first time the ZR-100 has been used for steam generator ISIs in China. SNPSC accurately located all the small indications it found during the pre-service inspection (PSI) using Zetec’s integrated eddy current solution.

“Zetec played a vital role in the support of our inspection team,” said Guo Yun. “The use of automation and a best-in-class integrated inspection system equates to substantial economic improvement for the power plant, increased reliability for our customers, and a higher margin of safety for our technicians.”

Zetec is a global leader in nondestructive testing (NDT) solutions for the critical inspection needs of industries the world counts on every day. To learn more, contact Zetec today!