Understanding the Total Focusing Method in PAUT

Being able to detect a flaw when it’s still tiny can save companies thousands—or even millions—of dollars worth of repairs. After all, it’s easier to repair a pinhole or crack in something like a pipeline than to resolve a full-scale rupture. Unfortunately, at times it can be a challenge to get accurate details of minor flaws to address them effectively. A good strategy for these more challenging inspections can be to use the total focusing method with phased array ultrasonic testing (PAUT).

The total focusing method is a unique algorithm that uses the data garnered in ultrasonic testing on a deeper level. With the right equipment, it’s possible to locate tiny flaws even in a material that’s traditionally hard to read. The total focusing method helps to make PAUT much more sophisticated while minimizing the risk of human error.

Issues with Accuracy in Ultrasonic Testing

Conventional ultrasonic testing makes use of soundwaves to locate incongruities in parts. A probe—or transducer—is passed over the material, and a high-frequency sound wave sent out. In some cases, that wave will return to the same probe for a reading based on the echo it creates. This method is called a pulse-echo ultrasound. Another technique is transmission mode, which sends the sound wave to a separate receiver. Imperfections between those two points will diminish the sound wave.

Ultrasonic NDT is a popular inspection method for a myriad of reasons. Some include:

- The ability to test a wide range of materials

- Technicians only need single surface access to inspect the item

- It poses no health risks to users, unlike other methods like radiography

- Incongruities are discoverable regardless of orientation

- Tests are relatively rapid, and surface areas require minimal preparation

While ultrasonic NDT does offer a wide range of benefits, it’s important to remember that much of the accuracy of readings depends on the operator’s skill. Poor operation will result in inaccurate results. Aside from that, there are a few limitations inherent in these types of inspections:

- Limited range: Sound waves may not reach every part of the inspected object, limiting result accuracy. Conventional ultrasonic NDT is not ideal for testing across long distances.

- Alignment issues: An uneven surface can result in poor alignment that gives inaccurate readings and false positives of flaws.

- Material limitations: Large grain materials, like austenitic steel, are challenging to read as the particles can block the sound wave.

- Dead zone potential: A dead zone in ultrasonic testing occurs when a returning signal interferes with the entry sound. The interference creates an area where no flaws are detectable. This issue is common in austenitic steel.

These issues can result in unnecessary repairs or downtime for equipment, so it’s critical to find ways to work around them. One option is to leverage PAUT rather than conventional single probes.

How Phased Array Enhances Results

PAUT eliminates many of the issues common in conventional UT by increasing the number of elements housed in a single unit. They sequentially pulse out sound waves and collect data as it returns. These probes can position the soundwaves at multiple angles to increase the inspection area.

| Attend the on-demand Total Focusing Method and Full Matrix Capture webinar for a closer look! |

PAUT is capable of detecting more flaws than conventional UT, including discontinuities that may be at awkward angles that are challenging to locate. It also speeds up the inspection process and allows for the evaluation of larger parts.

However, the increased accuracy of PAUT does come with one caveat. That is in the large amount of data it collects for more advanced inspections. A standard PAUT could result in lost data as all the aggregate information comes back as a single summary. A more advanced algorithm is required to make use of all the data collected.

Using the Total Focusing Method to Refine PAUT

The total focusing method algorithm is a means of leveraging PAUT data for better, more accurate readings. No information is summarized. Instead, it’s broken down to a granular level. Each transmitter/receiver from the probe’s array has its result digitized. Then, the algorithm calculates the focal law for each pixel. This process is much more detailed than the single assumed focal law and a summarized signal. As a result, it provides a thorough picture of the part under inspection.

With this method, it’s much easier to find and accurately detail tiny flaws that may have escaped detection before. It’s also a way of eliminating inspection dead zones by using multiple signals to overcome interference that leads to unreadable areas.

Not all ultrasonic equipment is capable of supporting the TFM. Typically, the user will need full matrix capture, a method where each probe sends out an individual signal but receives all the returning signals. Then, all this information goes into a matrix. For example, a probe with four elements would have a matrix of 16 A-scans. This grid of data provides the information needed for the total focusing method to create detailed inspections.

The total focusing method is an excellent option in more challenging inspections for overcoming the many challenges involved in gaining an accurate ultrasonic reading. Teaming it with the appropriate phased array probes can maximize data collected and ensure more detailed results. This method is ideal for locating small flaws that may have been undetectable in the past.

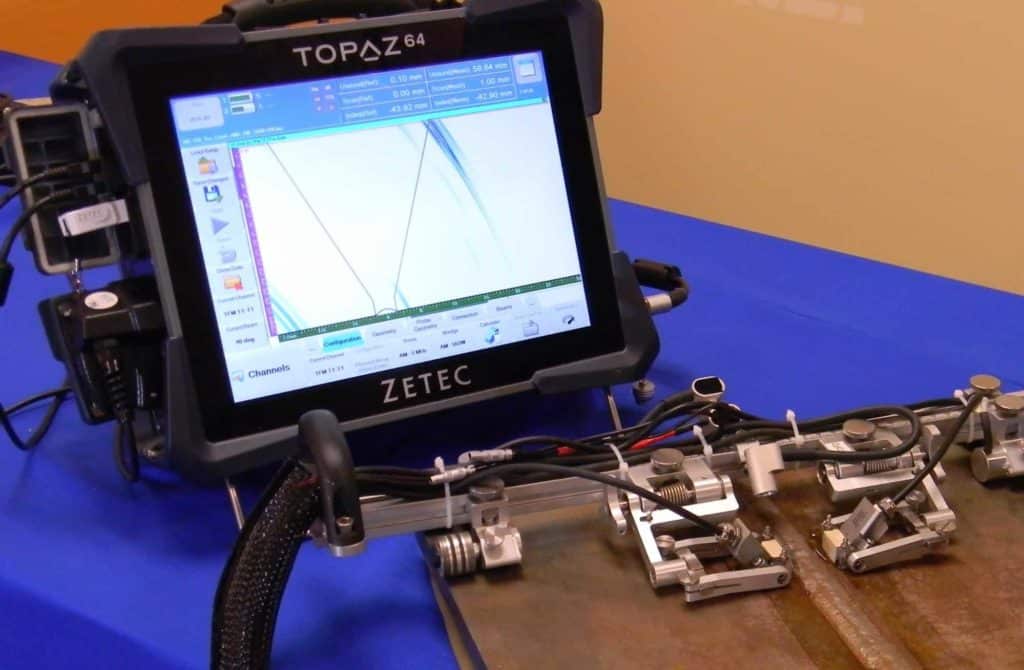

Zetec provides highly detailed results through a combination of full matrix capture and the total focusing method. Check out our ultrasound instruments or visit our contact page for more information.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.