Top 3 Advantages of Using PAUT for Weld Inspection

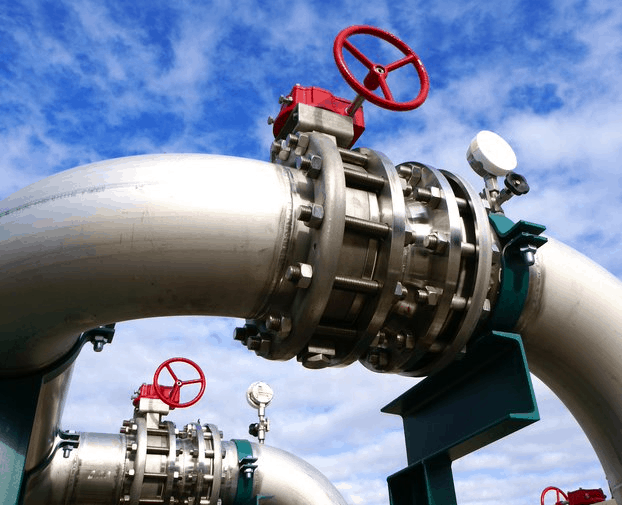

Weld inspections are often a major component of a large company’s NDT program. Especially in industry segments like midstream oil and gas, which deals with extensive pipe lays, weld inspections can be disproportionately represented. The sheer volume of welds, and their presence in critical, no-fail applications, requires companies to expend significant time and resources testing and maintaining them.

Ultrasonic scanning is the most effective NDT method for ascertaining weld integrity. This method transmits high-frequency sonic pulses into welds. By analyzing the reflectance or transmittance of the sound, ultrasonic instruments can locate internal, invisible flaws and defects. This can simply and quickly identify whether a weld is safe to remain in service.

The Benefits of Phased Array Ultrasonic Testing

However, even conventional ultrasonic scanning has drawbacks, and the complex geometry of welds can impose difficulties. The pulses of sounds which ultrasonic probes emit don’t cover the entire weld area, requiring multiple passes and probe angles to measure even a small section of weld. This slows the process significantly, and increases the likelihood that a flaw will be missed.

To increase efficiency, companies developed a newer style of ultrasonic testing. Called phased array ultrasonic testing (PAUT), this method uses powerful instrumentation, software, and probes equipped with multiple transducers. Using multiple transducers allows the probe to emit a continuous beam of sound, covering more area at once. It also allows technicians to adjust the beam’s angle without moving the probe, which helps overcome the difficult geometries found in pipeline and other welds.

Phased array ultrasonic testing has several advantages over older standard ultrasonic testing methods:

Speed: Phased array ultrasonic testing has a larger coverage area than single-probe methods. This allows technicians to scan more at once, reducing the amount of time needed for inspections. PAUT additionally allows technicians to adjust beam angle using software, reducing time spent manually adjusting probes. Phased array probes also simply require less set-up and preparation. The combination of these factors makes PAUT a significantly faster and more efficient means of weld inspection.

Simplicity: While the technology involved is more complex, most advanced phased array ultrasonic equipment is actually simpler for technicians to use. With fully integrated PAUT instruments, the setup requires less effort. Scans are controlled using powerful, intuitive software, which aids technicians and streamlines the inspection process. In short, utilizing PAUT makes mistakes far less likely to occur, if at all.

More Comprehensive Results: The complex geometry of welds can create difficulties for single-probe ultrasonic testing. Some flaws—especially those that are parallel to the center, skewed, or at transverse angles to the path of the probe’s beam—may go undetected. This creates a dangerous situation where welds may be closer to failing than an organization realizes. PAUT can detect these flaws, improving testing reliability. The greater volume of the beam and more effective beam controls allow technicians to remove the geometric areas in which flaws “hide” from probes. The result is more comprehensive testing and safer operations.

Choosing the Right Ultrasonic Testing Equipment for Weld Inspections

Phased array ultrasonic testing is the best nondestructive testing method for weld inspections. However, some phased array equipment is more aptly suited for weld testing than others. Ultrasonic testing equipment for welds should be lightweight and portable enough to allow technicians to easily transport it along a pipe lay or from site to site.

Equipment should also be rugged and durable, able to handle the difficult environments encountered at remote sites. At a basic level, equipment should be resistant to heat, cold, vibration, dust, and moisture. It should be battery powered, and preferably capable of hot-swaps to allow continuous operation even when power runs low.

Software enables technicians to operate their PAUT equipment. Software packages should have powerful built-in features yet be intuitive, and simple to operate. Appropriate filters and visualization options should be included to help technicians spot difficult flaws. The software should also be able to save scan results, and report them to a central database in order to preserve records for internal or external audits.

PAUT improves weld testing performance over single-probe ultrasonic testing and other NDT methods. Choosing the right ultrasonic testing equipment can increase efficiency, improve test reliability, and provide company managers the peace of mind of knowing that their welds will hold.

Zetec provides exceptional phased array ultrasonic testing equipment for weld inspections. To find the equipment which best suits your testing needs, contact us today!

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.