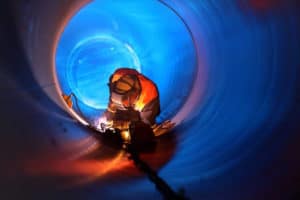

A High Temperature Hydrogen Attack (HTHA) campaign is one of the most difficult nondestructive testing (NDT) inspections. The challenge is

Read More

High temperature hydrogen attack (HTHA) crack inspection can be difficult to detect, so NDT personnel need an inspection discipline that

Read More

The inspection of aluminum plates calls for a nondestructive testing (NDT) method that can probe through multiple layers and thick

Read More

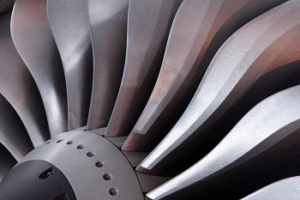

Forgings in the form of turbine discs, rotors, blades, and dovetails undergo heavy stress that can impede machine functionality. That’s

Read More

Gas turbine engines can harbor many undetected flaws that could hamper machine functionality. Years ago, liquid penetrant testing (LPT) was

Read More

Many NDT techniques have been used in the aerospace field, dating to the early days of flight. Two of the

Read More

Ultrasonic testing (UT) detects many types of aberrations that could jeopardize the integrity of infrastructure or assets. However, knowing the

Read More

NDT techniques allow workers to inspect welds, pipelines, holding tanks, risers, and other assets. As such, each technique has its

Read More

Due to the complex nature of nondestructive testing (NDT) hull maintenance tests, analysts need a special set of NDT procedures

Read More

The use of laser welding in the aerospace industry, particularly for aluminum alloys including AA6013, promises a more effective means

Read More