Overcoming Corrosion Mapping Test Challenges with Advanced NDT Equipment and Software

Instruments and probes are vital components when it comes to the nondestructive testing (NDT) process, but a viable mapping interface is just as important. When it comes to corrosion mapping techniques, the best equipment incorporates 3D rendering that affords users a comprehensive layout of all deviations. The mapping system should also be easy to read, with a simple user screen that’s accessible to NDT analysts of any level.

One of the main challenges associated with NDT campaigns is the level of confidence that the inspection solution is picking up all flaws, especially defects that some NDT solutions can to miss. However, quality mapping scanners and software not only aide in detecting minuscule anomalies but also determine the full depth of the corrosion relative to the testing radius. Two primary challenges associated with corrosion mapping include unconventional surfaces and shapes as well as software calibration. Luckily, advanced equipment and software can help analysts overcome these hurdles.

Corrosion Mapping Techniques Require Adaptive Functionality

It takes the right software, instrument, scanner, and probes to adjust to the curvature and surface of a tested item—not every NDT solution is suited for the job. An ill-positioned scanner or probe can cause alignment issues, resulting in flawed data that doesn’t paint a complete picture of the asset. Further, maladjustment leads to missed areas that could harbor harmful indications.

What’s more problematic is a conventional scanner that only provides a limited X-Y area over two axes. Many basic scanners cannot conform to smaller curved contours.

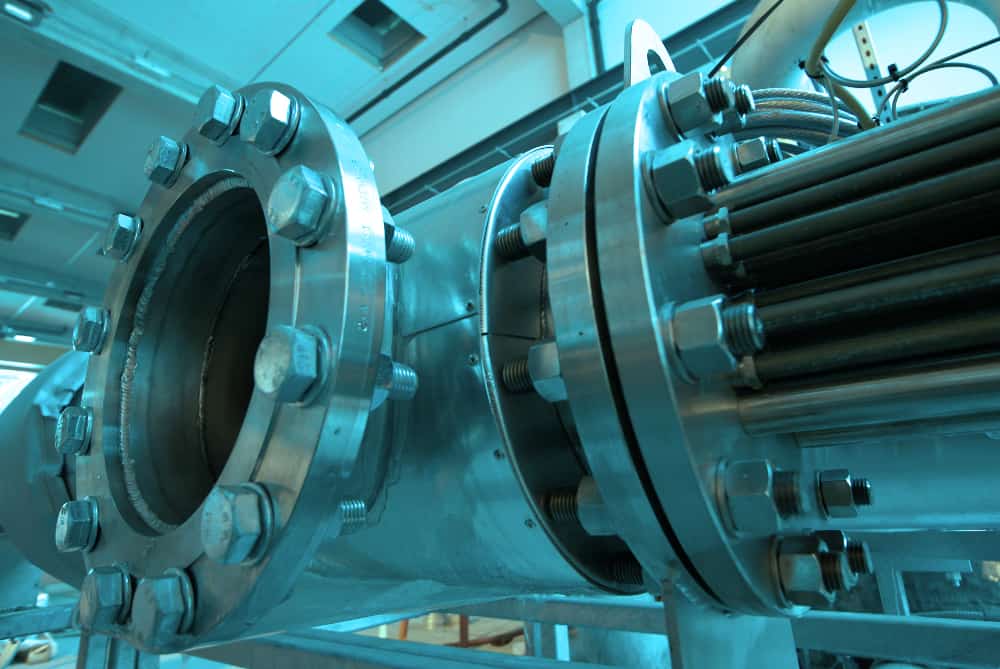

To comprehensively scan an object, analysts require a powerful solution that probes all types of surfaces, whether magnetic or non-magnetic. This makes flexible, adaptive equipment such as paintbrush scanners particularly ideal for corrosion mapping—especially when they come equipped with advanced UT instruments and software that can streamline the inspection process.

Example: An analyst must test a metallic weld at a natural gas processing plant, but the large size of the welded pipe renders the NDT process that much harder. The analyst uses the magnetic wheels of the scanner to cover wide segments of the curved exterior using several strokes across the surface. As the analyst moves the scanner, the system tracks the orientation of the probe. The scanner is wide enough to cover extensive areas with a few strokes, saving the analyst time and effort. The encoded wheels of the scanner also pinpoint uncovered areas live on-screen so the analyst can adjust accordingly.

Such advanced instrumentation can provide full coverage of the testing field, giving analysts peace of mind as testing commences. The software is a prime feature that enhances the probe during the inspection, fostering high-resolution mapping with flaws outlined on a more prominent level.

Software Processing Power Impacts Corrosion Mapping Techniques

When it comes to software, data analysis can be another barrier to corrosion map testing if the software offers few options in terms of setup. Data analysis can be a lengthy and laborious process. Outdated or ineffective software can lead to long setup times and even insufficient data analysis.

The best equipment simplifies the calibration so users can further identify defects while providing digestible data that’s easily storable. In terms of setup, the software behind a great instrument provides a 3D mapping system that permits extensive configuration settings, such as ray tracing using coverage mapping to assess inspection ranges and probability of detection.

Innovative software makes interpretation much easier. Analysts can produce the best results with the availability of simplified pre-set UT tools and settings for uncompromised data. Difficult setup processes can lead to additional adjustments that consume time during the testing phase, taking focus away from finding additional deviations. What’s worse is that certain NDT instruments do not provide detailed software adjustments, resulting in sub-par mapping techniques and limited analysis capabilities.

This type of software can perform the following:

- Powerful data analysis

- Real-time image displays of the signals

- 3D plotting for depth determination

These programs also allow analysts to identify probes that are connected to the instrument while establishing the necessary parameters. As the analyst utilizes the equipment, the software analyzes and stores all applicable data from the test.

Example: A novice analyst uses a paintbrush scanner to test a welding section at an oil refinery. The instrument allows the analyst to focus on finding pitting areas and corroded areas. The software presents the data collected in an easily digestible format, allowing the inspector to easily organize and analyze data, including pinpointing certain sections of data that will require further study.

That same analyst can detect any changes within the probe, so they can focus more on finding deviations within the asset instead of the probe itself. Innovative software produces uncompromised data that oil and gas companies need to maintain asset integrity. However, it takes the right kind of software to process all data successfully.

Corrosion Mapping Techniques Made Easier

The best equipment is flexible and conducive to many objects and probes. Quality mapping solutions can adapt to magnetic and non-magnetic surfaces, regardless of curvature or surface composition. With the right equipment, oil and gas companies can find more defects that could compromise upstream or downstream campaigns if defects remain undetected for long periods.

When it comes to corrosion mapping techniques, two major challenges include limited mapping capacity and the uncertainty of 100% area coverage. Flexible equipment featuring cutting-edge data-processing software can enhance maintenance budgets and prevent mishaps that could endanger staff members or the public. Therefore, it’s imperative that oil and gas companies purchase equipment from an experienced NDT company that creates innovative software, scanners and instruments.

Zetec provides cutting-edge NDT equipment and software that offers higher resolution and greater adaptability than conventional instrumentation. For more information, contact us today to learn more about our industry-leading corrosion mapping solutions.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.