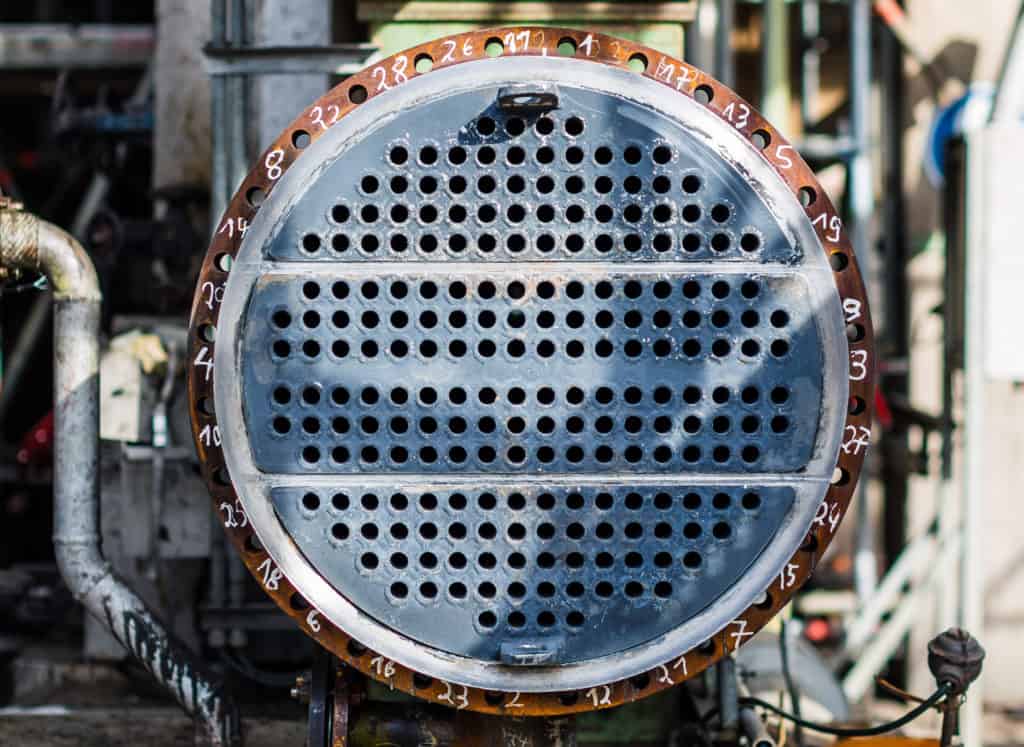

How to Improve Heat Exchanger Inspection Data Confidence with Automated Analysis

Going through a manual heat exchanger inspection can be a cumbersome process. NDT specialists must worry about confidently capturing every defect found within a tested item and picking up trending data while sifting through historical data. One of the most complicated processes entails the eradication of inconsistencies within traditional analytic measures.

It takes the right software technology and tools to streamline the analytic process and eliminate inefficiencies that can hamper the testing process. The best software automatically analyzes data in real-time as the user inspects a tested object. It also takes powerful, cutting-edge instrumentation and probes to successfully test and interpret results as accurately and thoroughly as possible. To get the best data, companies must combine automated software with high-quality nondestructive testing (NDT) instruments capable of detecting each and every flaw within a test object.

Heat Exchanger Inspection Software

Conducting a heat exchanger test manually is not an issue for trained NDT analysts, but not every NDT analyst has the skill and/or significant experience to interpret complex data without any variability or subjectivity among each other. Human error will inevitably play a role during the process at some point.

Additionally, small and large companies alike do not always have the resources and funds to train NDT staff members or hire skilled technicians that can consistently analyze results, regardless of who the analyst is at the time. With that, automated software for heat exchanger inspections is imperative, as it helps inspectors eliminate subjective interpretation or misinterpretation of unexpected or unusual variables. Regardless of skill level, an NDT analyst can commence the test and interpret results as the software streamlines data on a basic interface assisting throughout the process.

The right form of automated analysis software should include a simple interface with intuitive design and navigation. It should not disrupt current testing procedures in any way, and should be flexible enough to conform to existing operating plans. The software in question should ideally be powerful and precise, capable of capturing even the smallest, hard-to-detect indications, yet be simple and easy to use in order to help elevate inspection performance.

Example: An NDT entry-level analyst is inspecting tubing data using tubing array probes. While inspecting, they use powerful automated analysis software to analyze and report on circumferential defects. Even though the analyst is a novice, the software produces accurate results and reports as they probe in real time. It also analyzes the real-time data as inspections continue, eliminating the need to manually process the detections. When the inspection is over, the analyst does not have to devote extensive time to search all the data for indications, as the software automates most manual tasks and reviews. From there, the inspector can deliver high-definition data to their superiors with full confidence and in a timely manner.

Automation analysis software also greatly minimizes the potential for human error, in contrast to manual reviews. Human inspectors, for instance, might miss small changes and patterns that occur over time, but quality software will be able to pick up on such trends without fail, every time. Automated detection strategies can also prevent impromptu operations shutdowns if a tube fails without warning, thus increasing overall asset uptime. By increasing the speed and efficiency of inspections, automated analysis software allows NDT analysts to focus on their most important duties, such as signal evaluation and flaw detection. In fact, the right automated analysis software can enable an organization to increase inspection scope without adding any additional people, costs, or time.

Pairing the Right Inspection Software with the Right Instrumentation

Ideal eddy current (ECT) instruments for heat exchanger inspections will come with powerful signal processing, built-in probe pusher control, and support for a wide range of advanced probes. Automated analysis software will be able to process data more effectively when paired with a durable, reliable ECT instrument equipped with decisive data management systems and simple file transfer options.

Example: An NDT Technician from a certified NDT company is testing heat exchanger tubes for circumferential defects using the latest instrumentation, automated analysis software, and probes. The technician inserts the probe gathering the necessary data in a single pass. The combined features of bobbin and array functionality lead to shorter inspections times and less frequent changes of probes. In addition, the technician can use special array probes to get the best results when looking for circumferential flaws.

The best ECT instruments will be able to stand up to harsh environmental conditions of all kinds, including extreme heat or cold and radiation. Portable tools, in particular, make an analyst’s work that much simpler and swifter to complete.

Companies that offer the top-notch probing technologies have special patents that few companies can compete with. The best array probes have extensive coverage per coil density, allowing a for single-pass probing that yields data faster. Combined with the best instrumentation, NDT analysts will spot more defects in less time, saving companies precious time and resources with every inspection phase.

Refining Heat Exchanger Inspections with Quality Tools and Techniques

The key to obtaining stellar data from a heat exchanger inspection is to have automated software that optimizes the ease and speed of nondestructive testing procedures. It reduces the chance of human error and helps operators pinpoint important data that will help them make the best operating and maintenance decisions possible.

Defective tubing of any kind could disrupt operations or foster serious safety hazards. That’s why companies need automated software combined with precise ECT instrumentation that will provide them with the highest quality data and analysis. This will give analysts their best chance at consistently and accurately detecting potentially dangerous flaws well ahead of the critical stage.

For heat exchanger testing, Zetec offers a variety of powerful instrumentation and software to help analysts get the data they need when they need it—in high definition. To learn more about instrumentation and probing, contact Zetec today.

And, to learn more about using automated analysis software for heat exchanger inspections, be sure to check out our free webinar!

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.