Finding Ultrasonic Testing Training for Your Technicians

In nondestructive testing, as in any endeavor, having the right tools for the job is vital to success. However, it’s just as vital that your analysts possess the knowledge necessary not just to use those tools, but to utilize them to their greatest advantage. This requires intensive, specific training—and while some companies may choose to train their own employees, for many, the better choice may be to outsource training to a trusted third-party provider.

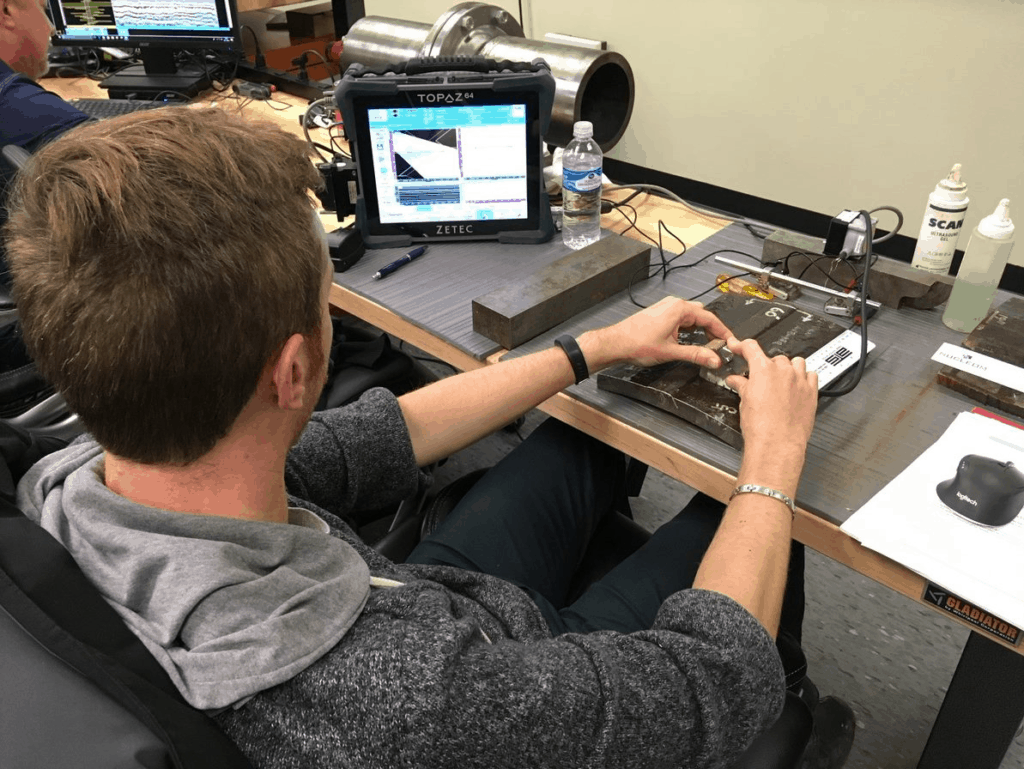

When searching for ultrasonic testing training, look for a service provider that can familiarize your analysts with state-of-the-art UT equipment and software. Training employees with top-notch tools can foster a seamless transition from the classroom to the field. Ideally, the products they train with will be the same as (or at least similar to) that which they’ll be using in the field.

UT training should also be level-specific, as analysts of different levels will require different focuses of study and degrees of difficulty. A reputable training company will assess how employees analyze data and support them during calibration procedures. The best training company opens its doors to entry-level and advanced analysts alike while training them with cutting-edge instrumentation.

Entry-Level Advancement

A thorough entry-level training course is a necessary foundation that lays the groundwork for an NDT analyst’s career path. Outsourcing this training allows managers to spend less time overseeing the work of a novice inspector, as he or she will be trained in conducting faster inspections and efficient data extraction methods using high-quality instrumentation.

A solid entry-level training course should cover the following::

Setting up UT equipment: Innovative instruments allow entry-level personnel to learn faster and save time on pre-inspection calibrations.

Conducting ultrasonic testing: Analysts should conduct on-site inspections under the supervision of an instructor. All testing scenarios should mimic real-world situations while introducing diverse scenarios that pose common and uncommon challenges.

Reporting the data: Analysts need to develop their analytical skills to be able to read and interpret results effectively and spot defects where indicated. Another core part of analytical training is the recognition of flaw depths, including the type of flaw detected.

Data reporting is a crucial component of an NDT inspector’s duties, but the type of analytical training depends on the UT method and the product used during the training program. Regardless, it behooves companies to work with a training company that combines high-level instrumentation with advanced software that makes data interpretation an easier feat.

In a similar vein, instruments and probes that are tailor-made to find precarious indications introduce novice employees to real-world challenges, giving them a leg up in the field by learning how to tackle the hardest defects at an early stage in their careers. Companies can take comfort in knowing that their employees are adept in detecting a wide array of anomalies, including ones typically reserved for higher-level personnel.

Advanced Studies

Level 2 and 3 analysts require more advanced ultrasonic testing training than their level 1 peers to ensure that they are well-equipped to handle any testing situation that may arise. Not only should these analysts acquire an even deeper understanding of ultrasonic testing methods and equipment, but they should also receive specialized training that will allow them to effectively oversee level 1 analysts’ inspections.

Ultrasonic testing training for level 2 and 3 analysts should include:

Core Competence: Analysts should be able to set up instruments based on the testing scenario without supervision. They must also be capable of calibrating the instruments based on such factors as welding type and object shape.

Analytical Procedures: Analysts must be trained to evaluate data and provide reliable recommendations that adhere to company guidelines and codes.

Leadership qualities: Upper-level analysts should supervise all inspections conducted by level 1 analysts. They must also guide new analysts and instruct them when necessary.

Leadership skills are especially important during level 3 training because this class of inspector typically assumes responsibilities for staff conduct and facility management. Level 3 personnel may also become instructors that teach other inspectors, and this is here where maintaining specialty training and retaining general NDT knowledge becomes especially valuable.

The Importance of Product-Specific Training with Advanced Equipment

What is the difference between a moderately capable level 3 analyst and one who excels? Often, the answer is the quality of the equipment they were trained with. An analyst trained in using state-of-the-art instrumentation will almost always be more proficient at detecting flaws and analyzing data than one who is not. Training with instruments that feature advanced pulsars, for instance, allows analysts to gain greater expertise in-depth penetration, as lower-quality NDT instruments are often not up to the task of penetrating thicker welds.

Likewise, while learning broad interpretation techniques that could apply to many UT instruments is certainly useful, product-specific training, or even application specific training is vital because it gives analysts the opportunity to learn how to collect and read data from a certain line of products for certain types of inspections—ideally, the same ones they will be working with over the long term. This level of specificity in training allows analysts to gain a depth of insight and familiarity with their equipment and scenarios that would simply not be possible with a broader approach.

The Advantage of Quality Ultrasonic Testing Training

A company that teaches little beyond entry-level or conventional UT is one that has failed to keep up with industry trends and innovations. As NDT technology continually evolves, analysts must keep abreast of advancements in the field in order to ensure efficacious inspection processes.

A truly quality training provider will be able to offer specialized training for analysts of all levels using leading-edge ultrasonic equipment. With the right ultrasonic testing training, analysts will be well-equipped to find flaws, interpret data, and provide recommendations that companies can rely on to keep operations running smoothly—and safely.

Zetec has been a leading name in the NDT industry for decades. We are proud to provide both high-quality equipment and in-depth product training for a variety of industries. To learn more about our ultrasonic testing solutions, contact us today.

Zetec’s designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices.