Boiler Tube Weld Inspection

Inspection Challenges

When inspecting boiler tube welds, outage time and resources are key inspection challenges. The industry requires a rapid volumetric non-destructive testing (NDT) technique to minimize these challenges. Traditionally, radiography (RT) is used, but has several drawbacks: it is insensitive to certain planar defects, there is no immediate feedback for the welder and it can be disruptive to other activities. Furthermore, workplace safety regulations are becoming more stringent and need to be factored into the process adding an additional challenge.

Recommended Solution

A reliable and efficient volumetric inspection solution without the disruption and potential hazards of RT is recommended. It involves the combination of the proper phased array ultrasonic (PAUT) and Time of Flight Diffraction (TOFD) techniques. The solution can effectively and efficiently deal with low clearance area, varieties of diameters, and the presence of weld caps. Furthermore, it can detect all defect types and offer through-wall sizing capability.

The proposed solution includes the following components and techniques:

A powerful and portable PAUT unit with all tools and features to efficiently set up and deploy the following:

- High-speed inspection: acquisition from 2 sides, in less than 1 minute

- One-line circular movement, with sectorial scan for weld coverage

- Full skip inspection: capability to use from 40° to 80°SW

- Accurate imaging using on-line S-Scan and Dynamic Merge

- Examination methodology adaptable to applicable codes and requirements

Scanner optimized for low clearance environments

Specifically designed low profile phased array and TOFD probes for this type of inspection, capable of completing the recommended examination techniques

Zetec Products

Zetec offers the optimal solution for this type of inspection challenge, delivering a highly reliable and efficient volumetric inspection. The following complete solution kit from Zetec features the necessary components and tools to confidently perform all the examination techniques in the inspection.

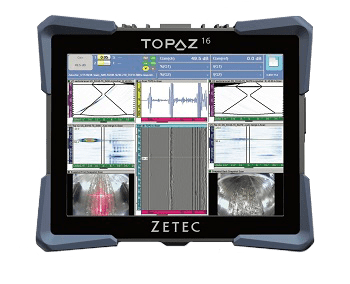

TOPAZ16 fully integrated, portable PAUT unit

TOPAZ16 is a 16 channel fully integrated PAUT device. Featuring best in class software capabilities, multi-touch screen and proven Zetec quality, TOPAZ16 delivers unmatched value. It is sized for convenience and built to perform. Features include:

- One instrument for everything: from preparation to reporting, TOPAZ16 is the complete solution. With easy setup and onboard analysis, reduce the amount of equipment needed to perform an inspection. Available in 16/64 or 16/128 configurations, TOPAZ16 is adaptable for meeting your specific inspection needs.

- Highly capable: ability to combine phased array and TOFD techniques simultaneously

- Industrially proven: driven by UtraVision Touch on-board software ensuring an efficient inspection workflow

- Highly responsive: multi-touch screen that not only offers the best resolution in its class but also one of the largest display size to instrument footprint ratios

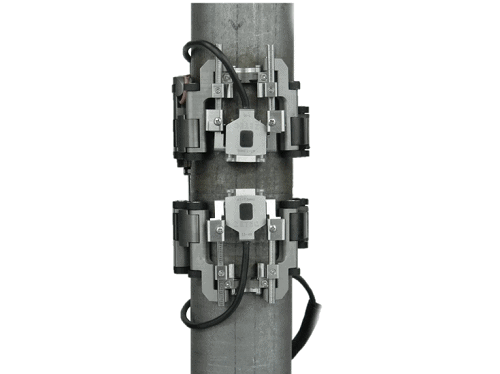

Circ-it scanner (from Jireh Industries)

Circ-it from Jireh Industries is a scanner optimized for low clearance

environments. Features include:

- One-axis manually encoded scanner

- Variety of diameters: from 21.4 mm to 114.3 mm (0.5” to 4.0” NPS)

- Low-profile design: radial clearance 11 mm

- Modular and flexible design: quick change links for infinite adjustment; single or dual phased array probe scanning configuration with or without TOFD

- Cable management system: for irrigation lines and probe cables

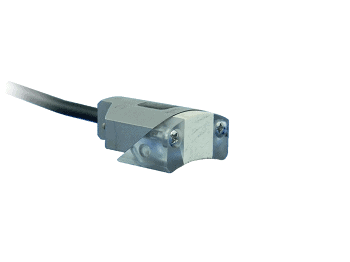

Low profile phased array probes and wedges. Features include:

- Extra thin 1D linear array probe: 11 mm (0.433’’)

- Curved array for optimized focusing in thin tubes: r = 35 mm

- Designed for sectorial scanning

- Multiple probe frequencies available

- 5 MHz for rough inspection surfaces (with OD pitting)

- 7.5 MHz for standard inspections

- 10 MHz for optimized detection and characterization of small volumetric indications (porosities, slag…)

- Choice of 16 or 32 elements to optimize steering capability

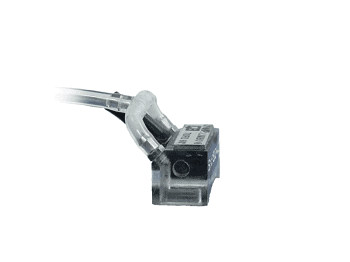

Limbo TOFD probes. Features include:

- Extra low 10mm profile dedicated TOFD probes

- Curved wedge specifically shaped to pipe diameter

- Integrated wedge removes need for transducer/wedge couplant

- 10 or 15 MHz frequencies available

- Multiple beam angles available

- 45, 60 or 70° nominal angles

- Choice of 3 or 6 mm element diameters

Benefits

Highly Efficient and Versatile

- One instrument handles the entire inspection — the Zetec TOPAZ16 includes the required tools and

- features to efficiently set up and deploy all recommended techniques. No additional instruments or

- software needed.

Industrially Proven

- This solution has been successfully deployed in the field featuring probes specifically designed for this

- type of application

Reliable and Non-Disruptive

- Confidently inspect boiler tube welds with better detection, sizing and characterization than RT

- Eliminate the disruption to operations as is common with RT